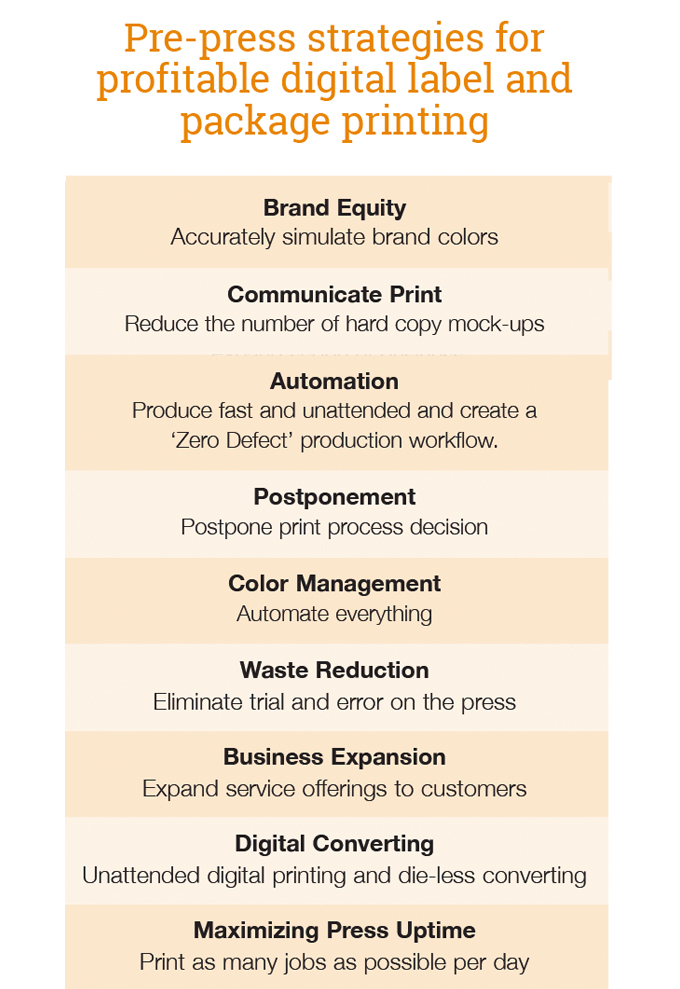

Pre-press strategies for profitable digital label printing

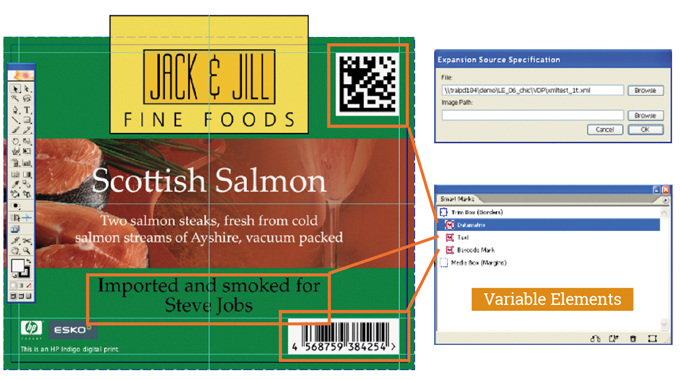

Digital printing is a very flexible process and enables shorter run lengths, reduced inventory and faster delivery times, as well as easy change-over for different versions and variations, the ability to offer personalization, and to undertake sequential coding or numbering. With some digital printing technologies it is also possible to gang together print jobs of different sizes, repeat lengths and quantities alongside each other on the web.

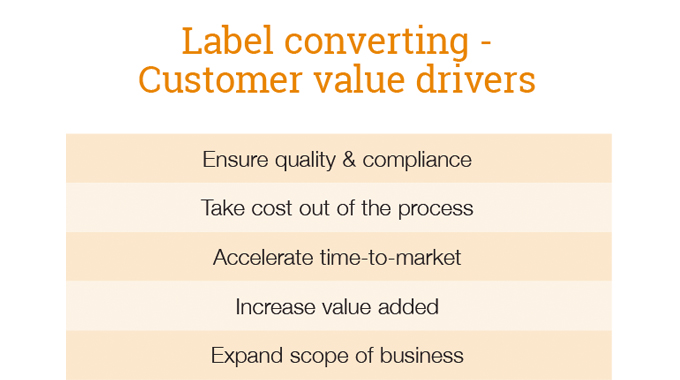

Label and package printing converters buy a digital press because they want to use some or all of these features to better service their customers – and also to increase their profitability. However, this almost immediately raises some technical questions, amongst the first of which is: is the printer/converter’s pre-press operation ready for digital print?

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.