Druk-ker increases shrink sleeve capacity with Omet X6.0

Hungarian converter Druk-ker has increased production capacity for shrink sleeves, in-mold and self-adhesive labels since the installation of an Omet X6.0 press in 2019.

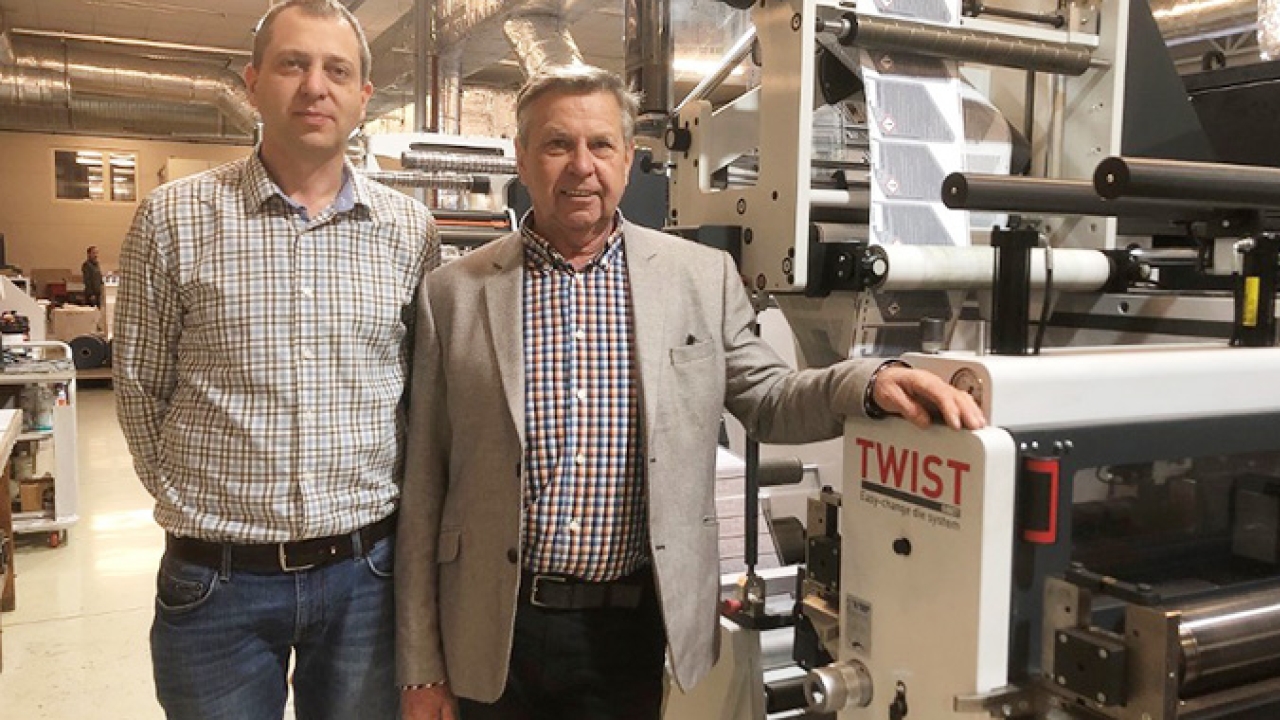

Druk-ker Nyomdaipari Kft is a Hungarian company founded in 1992 as a family business specializing in offset, digital, and flexo technologies. It is one of the shrink sleeve leaders in the country. The company has over 70 employees at over 3,000 sqm headquarters in Kiskőrös and Budapest sales office.

‘Our aim was to build a stable production site, with at least two machines for each production process. Nowadays, we can proudly say that we are the leading shrink sleeve producer in Hungary. Still, the most important thing is that we can serve our valued customers for any kind of labeling technologies,’ said Péter Markó, managing director and son of the Druk-ker founders.

‘We have always been attending the most important fairs and exhibitions of the label industry, so we could see the amazing evolution of Omet, which became one of the biggest and most advanced press manufacturers. XFlex platform attracted us immediately when presented to the market,’ added Markó. ‘We had to wait for the right moment with the right circumstances. In 2015 we had the chance to buy a used XFlex X6 430 press. We were very satisfied with the performance, so in 2018 we decided to invest in a new X6.0 530 machine.’

According to Markó, investing in Omet brought more efficiency to Druk-ker’s production lines. Thanks to the sleeve technology and the Twist die system, it can do rapid job changes and records less downtimes. Thanks to the automatic register control system, the company has less set-up waste and better register stability. The automatic pressure adjustment system makes it easier to recall repeating jobs.

In 2019 the company has also installed a Heidelberg XL 75-5L UV sheet-fed offset machine. The increase in printing capacity brought the need for a converting section as well, so Druk-ker also installed new shrink sleeve seaming, inspection, cutting machines, and an in-mold labels die-cutter.

‘Our dream would be to have a hybrid rotary offset and flexo press on the X-Flex platform, but first, we should see our financial possibilities and the upcoming market demands,’ concluded Markó.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.