Gallus installs three Labelmasters in Czech Republic

Gallus has installed Labelmaster presses at OTK Group, Colognia Press and Králíček, three of the leading label converters in the Czech Republic. For each printing house the machine has been configured differently.

The flexo printing house Králíček, with about 40 employees, has been focusing on self-adhesive labels since the beginning, and now they constitute to approximately 95 percent of the production. The company started working with Gallus presses more than ten years ago with the Gallus EM 280 which is still in production.

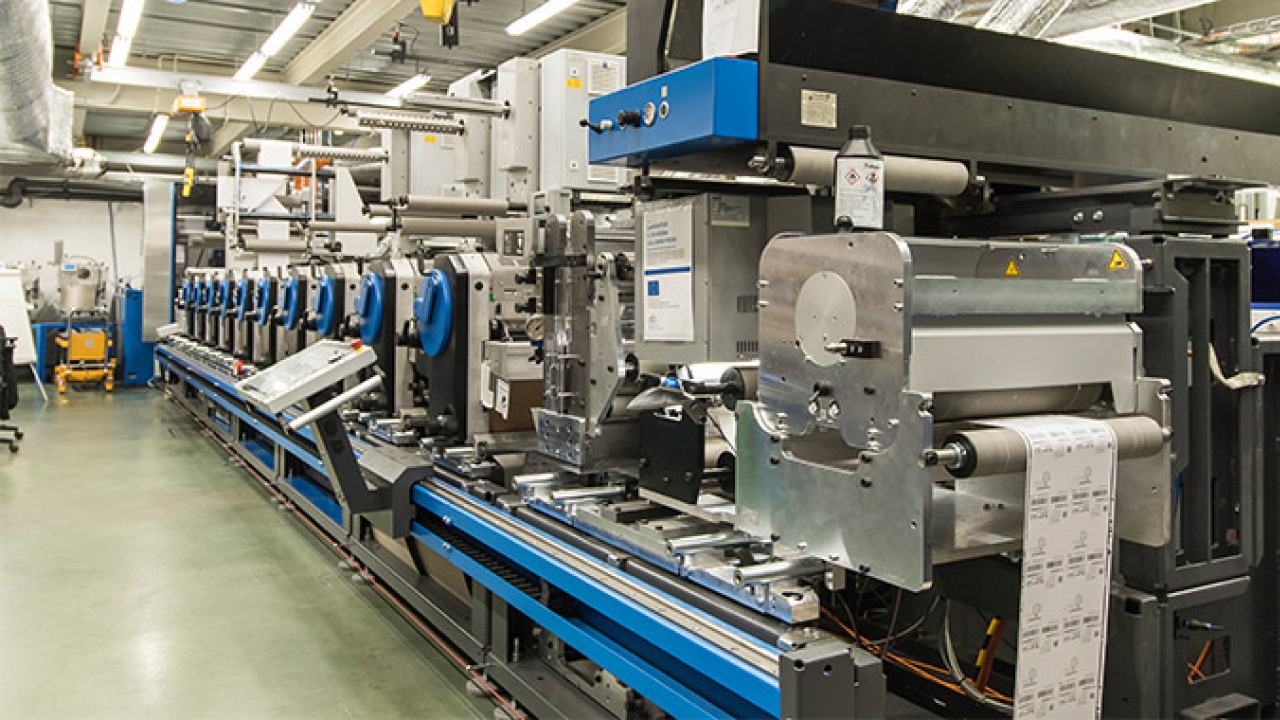

Králíček has moved into a new, modern production facility in Hlubočinka – Sulice near Prague in 2019 and ordered the first Labelmaster 340 press in the Czech Republic. It features printing width of 340 mm and eight flexo printing units in total, including printing on glue, cold foil and a die-cutting unit.

‘The development of the jobs we process made us extend our equipment base. Thanks to good relationships and experience, we decided for Gallus Labelmaster 340,’ said Petr Králíček, the owner of Králíček. ‘We were attracted also because it was the first installation in the Czech Republic. The first machine we got from Gallus was the one that enabled us to get to a higher level of label printing.’

OTK Group, Kolín-based company founded in 1879, has implemented its new investment program in the technology area for flexible packaging and self-adhesive labels. It was the increase of shrink sleeves production effectiveness, that made them invest in a UV flexographic press Gallus Labelmaster 440. The press with 440 mm printing width features nine flexo printing units, two die-cutting units, printing on glue, cold foil and UV drying system. The new press is not the first Gallus machine in this printing house as the group already runs several machines from the EM model line.

‘In the past years we have invested in modernization and capacity increase of narrow web machines. Following the purchase of two EM model line machines, Gallus Labelmaster was an obvious choice,’ said Tomáš Latinák, business unit director OTK Group. ‘This machine allows us to print all product groups from our portfolio, moreover the new technologies significantly increase production productivity.’

Colognia Press, also based in Kolín employs 130 people and focuses on the production of special packaging and labels (self-adhesive labels, safety, peel-off and smart labels, clear blank labels, Braille labels and graphic art labels shrink sleeves). Its new Gallus Labelmaster is the one with the highest possible configuration with the printing width of 440 mm, 10 flexo printing units, hot foil and cold foil unit, non-stop unwinder and rewinder form Martin Automation, 100 percent inspection, printing on glue, two exchangeable flexo units, two die-cutting units.

The company’s choice of the Labelmaster is also based on its good experience with other Gallus machines, both the oldest EM 280 and two newer machines of the highest RCS 330 model line.

‘The main reason to buy this machine are the possibilities of research and development of new products,’ commented Bohdan Holona, DTP manager Colognia Press. ‘The machine serves for collecting data in real time, which we use to develop new solutions. Gallus Labelmaster enables us to test these innovations under our roof in a real production environment.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.