Hybrid Software marks 1000th installation

Hybrid Software has met a significant business milestone, recording its 999th, 1000th, and 1001st customers: Tempo Plastics, delo and NSD which have recently installed Hybrid’s products in their facilities.

‘As can be seen with our three latest Hybrid Software customers, there are many diverse reasons why companies choose to work with us,’ said Guido Van der Schueren, chairman of Hybrid Software. ‘That said, they all share one desire: a need to work with a company that is willing to become more than a vendor, but a partner.’

Tempo Plastics Limited, based in Innisfil, Ontario, Canada manufactures over one million packages every day producing pouches, polybags, and rollstock for a wide range of markets. The converter needed a customizable online system to manage external approvals and to track internal production processes.

‘Like many companies in the labels and packaging market, Tempo Plastics faced challenges that sometimes cannot be resolved with out-of-the box technologies,’ said Dino Loiselle, Hybrid sales manager for Canada. ‘Because of the nature of its business, Tempo Plastics’ specific processes, methodologies and existing systems were supplied by a number of different manufacturers.’

‘In order for us to be successful, it was crucial that our proposed technology could be integrated in the shortest period of time possible, and at a price that would generate a substantial return on investment for Tempo Plastics,’ commented Mike Agness, executive vice president of Hybrid Software for the Americas. ‘We created a Cloudflow configuration for Tempo Plastics that delivers exactly that, providing a hybrid platform which leverages market standard file formats and customizable interfaces. It efficiently connects people to their systems.’

Based in Lohne, Germany, delo is a historic player in the packaging foil and foil wrapping industry, operating one of the largest flexographic printing plants in Europe. As part of its digitalization initiative, delo chose Hybrid Software as its partner. delo’s project priority was building a communication platform to allow its customers to manage files and data.

Christopher Graf, chief marketing officer of Hybrid Software commented: ‘Constant innovation and Hybrid’s open product standards ensure substantial productivity gains, maximum production quality, and the growth of our customers.’

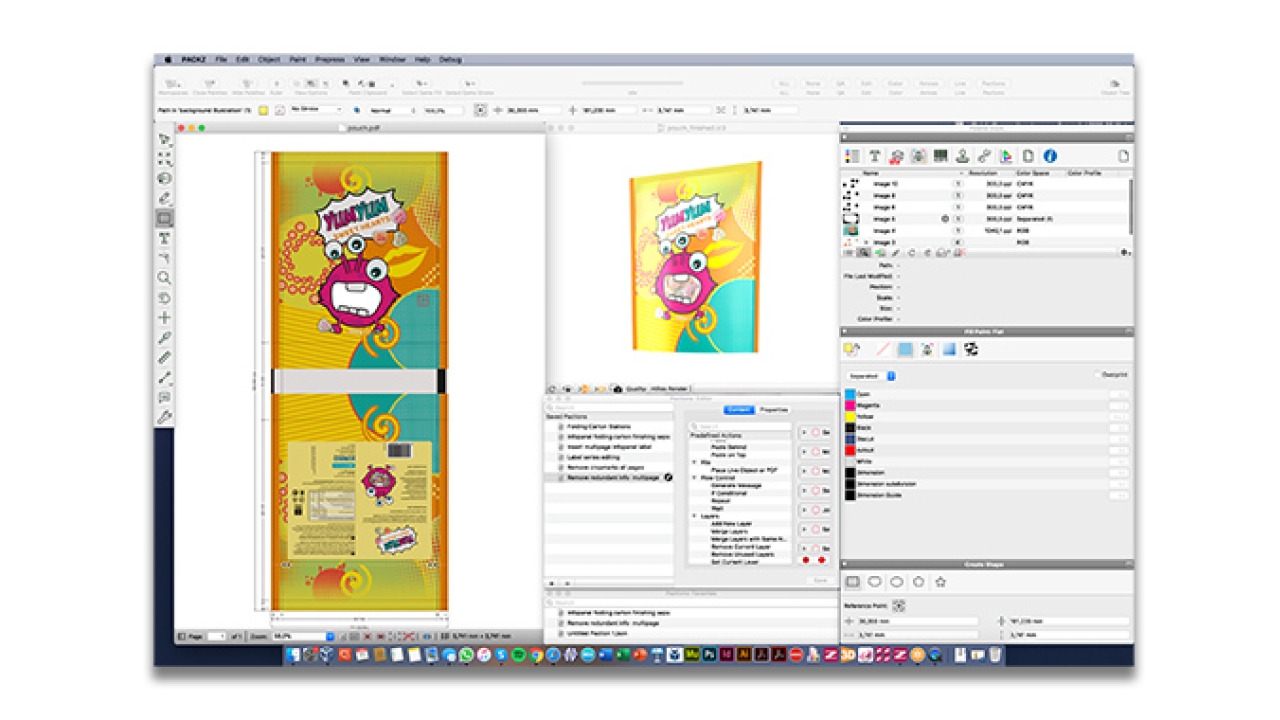

NSD International in Scotland traces its roots back to 1976 as an experienced supplier and in-house producer of self-adhesive labels. The company is capable of printing on any kind of paper, foil, and other materials—with a variety of inks and folding required. NSD has invested in Packz software for PDF preflighting and editing in its company studio.

Martin Miller, operations manager at NSD said: ‘The overarching factor for switching to Packz was its ability to shorten our design and prepress times significantly and automate our digital workflow. Our labels can typically utilize multiple colors, and include foils, embossing and varnish, and often with variable data numbering for casks and bottles. Our business model relies on agility and adding value by providing our premium brand drinks customers quick and agile supplies of highly sophisticated labels.’

‘Hybrid Software is proud to be a very viable option for companies looking to build, or renovate, their packaging prepress production automation processes. We have a wide range of needs among our 1,000 customers that demonstrates our ability to succeed in just about any use case. We have always welcomed the challenge to partner with new companies and implement demanding prepress systems,’ concluded Van der Schueren.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.