Intalabel boosts production with Edale FL3 press

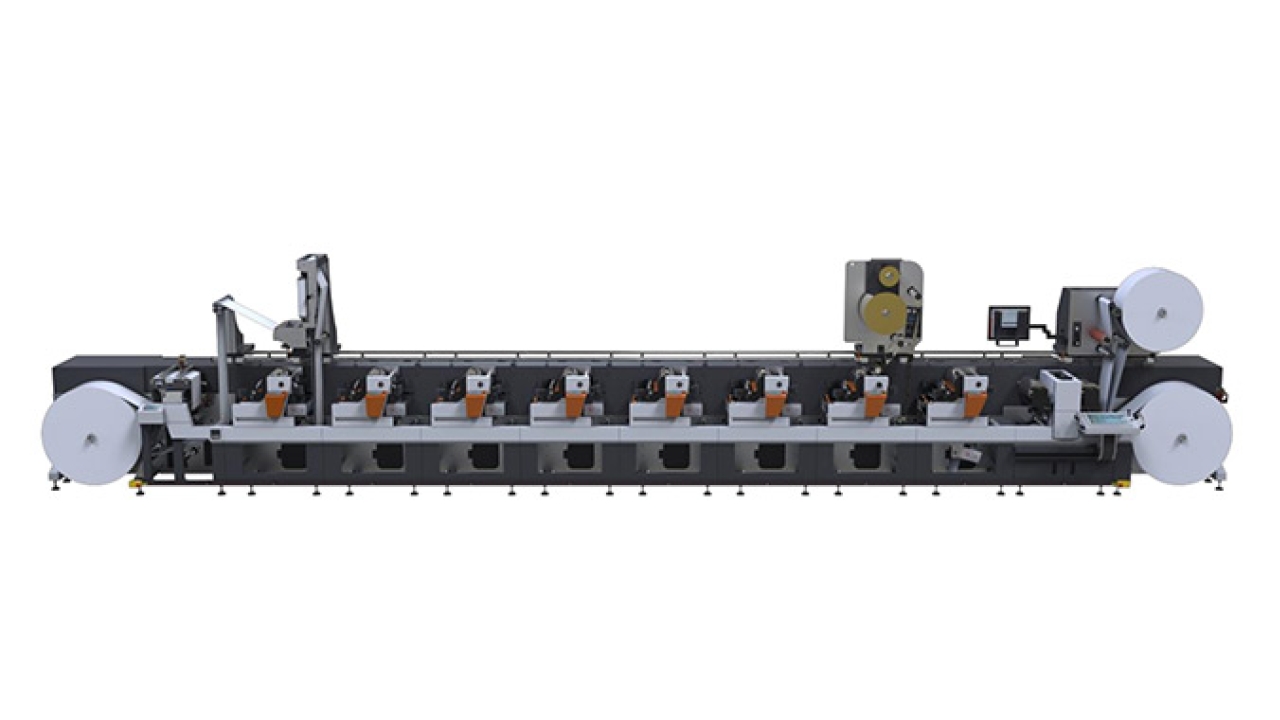

British label converter IMV Packaging Limited Intalabel (Intalabel) has invested in a highly automated Edale FL3 press to increase its production capacity and diversify into new market sectors.

Based in Hull, UK, IMV Packaging Limited Intalabel is a self-adhesive label manufacturer specializing in designing, manufacturing and supplying various label and packaging options manufactured to ISO standards with BRC AA accreditation.

The FL3 installed boasted an array of options that help reduce time, keep setup time to a minimum and reduce operator inconsistencies throughout a run or shift. This included Edale’s AiiR, a motorized print impression, anilox pressure and a cross-register control system.

Intalabel also opted for the semi-rotary die-cutting system, the main benefit is that the magnetic cylinder does not need to change when moving from one format size to another. This can reduce downtime between each job and increase safety in the workplace.

David Littlewood, director of Intalabel, said: ‘Our FL3 has been in production for over a year, and we have seen first-hand the benefits of flexographic technology. We wanted to invest in a press that would enhance our label production process and one that would suit our growing business needs and cope with the quality demands from our clients on a vast range of substrates we produce labels on.

‘The FL3 gives us ease of operator use, superior print quality, quick setup, and reduced waste. It has certainly lived up to our expectations and enabled us to grow our business by providing the service and quality that Intalabel stands for.’

‘We are delighted that Intalabel has chosen the Edale FL3 as its next step in the company expansion,’ added Darren Pickford, sales and marketing director for Edale. ‘The addition of semi-rotary die-cutting and auto set slitting allows easy and cost-effective conversion of what would have been digitally run work to Flexo and this is already proving successful for Intalabel. We look forward to continuing to work with Intalabel as they continue to grow.

‘Intalabel’s investment strategy was based upon the continued improvement on the Edale FL3 servo-driven technology, plus the merits of HD flexo reprographics to have the option of compatibility in the workflow, allowing Intalabel to offer the client both short-run UV inkjet and HD flexo capabilities without a definable print quality compromise.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.