JUB Group invests in three Herma 500 applicators

JUB Group, one of the leading European manufacturers of paints and renders, has invested in three Herma 500 applicators for its in-house production process to achieve labeling accuracy despite the challenging weight, complex shape, and large labels needed for its products.

Headquartered in Slovenia, JUB Group operates 12 subsidiaries in central and southeastern Europe and has more than 700 employees.

Labeling large paint buckets poses several challenges because of their size, weight, and shape. The container’s oval and slightly conical shape and constantly changing distance from the applicator during the labeling process add another difficulty in applying labels accurately and reliably without any creases or bubbles. Since the labeling machine was to be operated in a JUB Group production and filling facility, the technology also had to be rugged and compact.

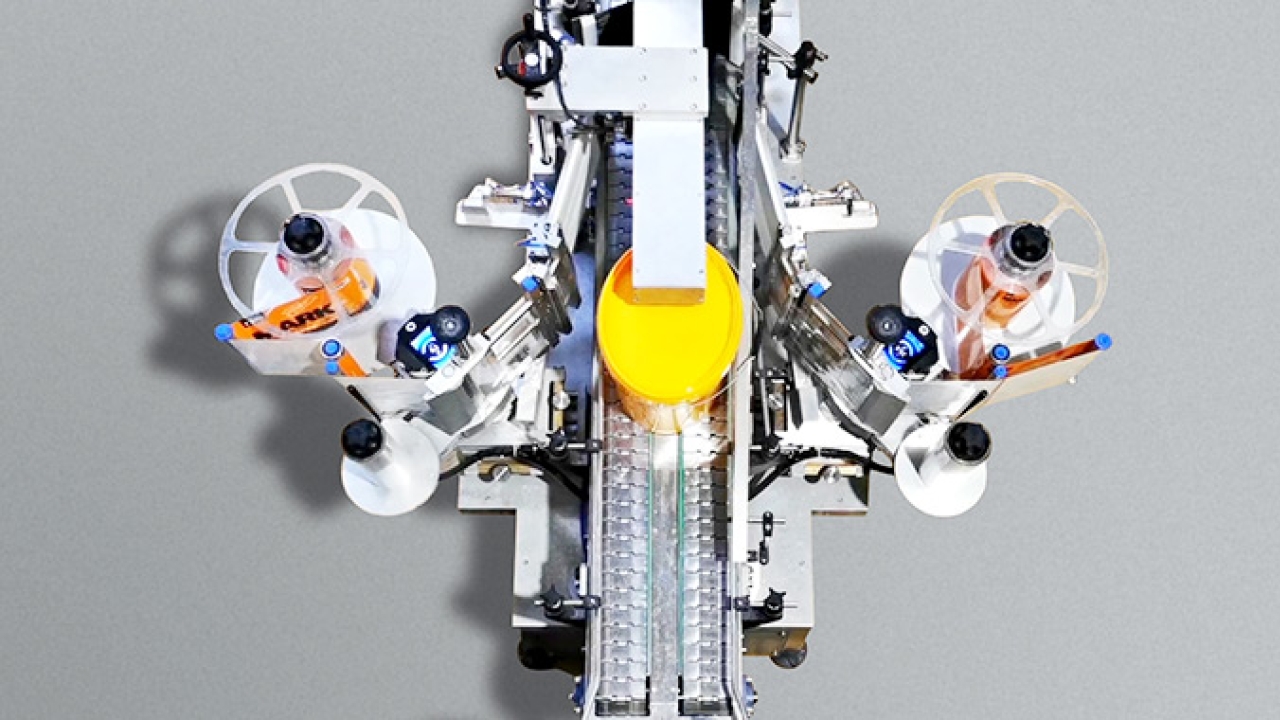

The Serbian packaging and labeling specialist Elmed, a sales and service partner of Herma for many years, has originated a technology to overcome all these challenges. It includes three Herma 500 applicators.

As the paint buckets arrive from the filling line, the products are automatically transferred by conveyor to the bucket labeling machine devised by Elmed. A special belt tracking system ensures exact alignment and a centrally located top belt provides additional stability within the machine.

Since each of the two side labels is larger than an A4 sheet, they cannot be applied using conventional rigid peel plates. In their place, Elmed developed special vacuum tamp pads that can traverse all three axes and apply labels to the three relevant surfaces.

The labels are first transferred from the peel plate to the tamp pads, which apply them to the buckets with a pneumatic system. To ensure that the labels hold especially fast, additional pressure is applied by brushes or rollers. A different label is applied from above to the bucket’s concave lid. No special tooling is required for this purpose. This solution enables JUB to label as many as 12 buckets of paint a minute.

‘We are highly impressed by the system’s precision and smooth operation,’ says Zagorka Mikić, technical manager of the JUB production facility near Belgrade. ‘The Herma 500 has a highly intuitive user interface. You can use it with or without gloves, which is ideal in production environments. The menu structure is designed so that no more than three clicks are needed to reach the desired menu item.

‘Changes are quick and easy when a new label roll is needed because favorite parameter settings can be displayed directly on the start screen. On top of that, dust or other unavoidable particles can be removed from the touchscreen with practically any conventional product.’

‘Since conducting the initial training in the JUB facility, we have not received any queries relating to the machine’s operating principle or everyday operation,’ commented Elmed managing director Ivan Crnojević. ‘That’s testament to the vast experience of our client’s operators and the care that they take. It also demonstrates that our labeling machine, equipped with the three Herma 500 applicators, operates very consistently and reliably and satisfies the unique requirements of this application perfectly.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.