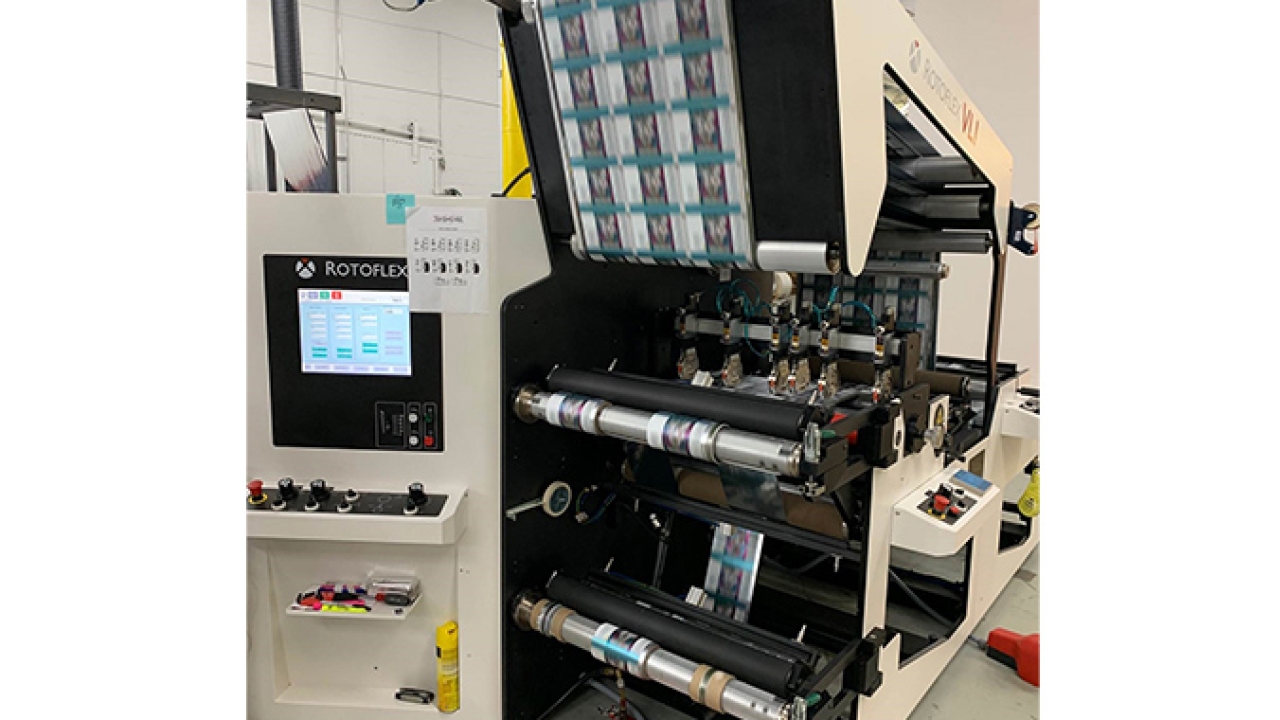

TQL Packaging Solutions installs Rotoflex VLI 700

Dallas-based converter TQL Packaging Solutions has invested in Rotoflex VLI 700 28.5in-wide inspection, slitting, and rewind system to further expand its production into the packaging market.

The company, founded by the current president, Scott Smith, in 1995, as a startup on a shoestring budget with himself as the sole employee quickly grew in the pressure-sensitive market. The converter is celebrating its 25th anniversary in 2020, offering digital and flexo technologies for conventional labels up to complex packaging applications like pouches, shrink sleeves, and extended-content labels.

Despite the pandemic’s economic pressures, TQL Packaging Solutions has installed Rotoflex VLI 700, a premier 28.5in-wide inspection, slitting, and rewind system that complements advanced applications and high-volume production.

Before choosing the machine, the company closely evaluated Rotoflex alongside other solutions in the market, and the speed of VLI was the deciding factor.

‘We needed enough speed to keep up with our newly acquired 26in flexo press, which was installed over the summer,’ says Smith. ‘VLI runs two daily shifts at an average of 1,000 ft/min. Upon installation, we had three million linear feet ready for the machine to slit, and I estimate that the machine was able to slit 20 million feet in the first weeks, which is far better than I could have imagined. It’s so important, especially on film work, to have rolls with crisp edges, just like a mirror. This is one of the areas the VLI really shines.

‘We had two days of training which, by the way, was another great thing. Rotoflex came in the middle of Covid-19 and did the training in a very professional and safe way, keeping distance and wearing a mask all the way through. On top of it, training was multi-lingual, and that is valuable. I also expected to be a little bit more of a learning curve, but right off the bat, we were able to easily run from small rolls to almost maxing the machine out.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.