US flexible packaging printer upgrades converting capability with Comexi slitter with integrated laser module

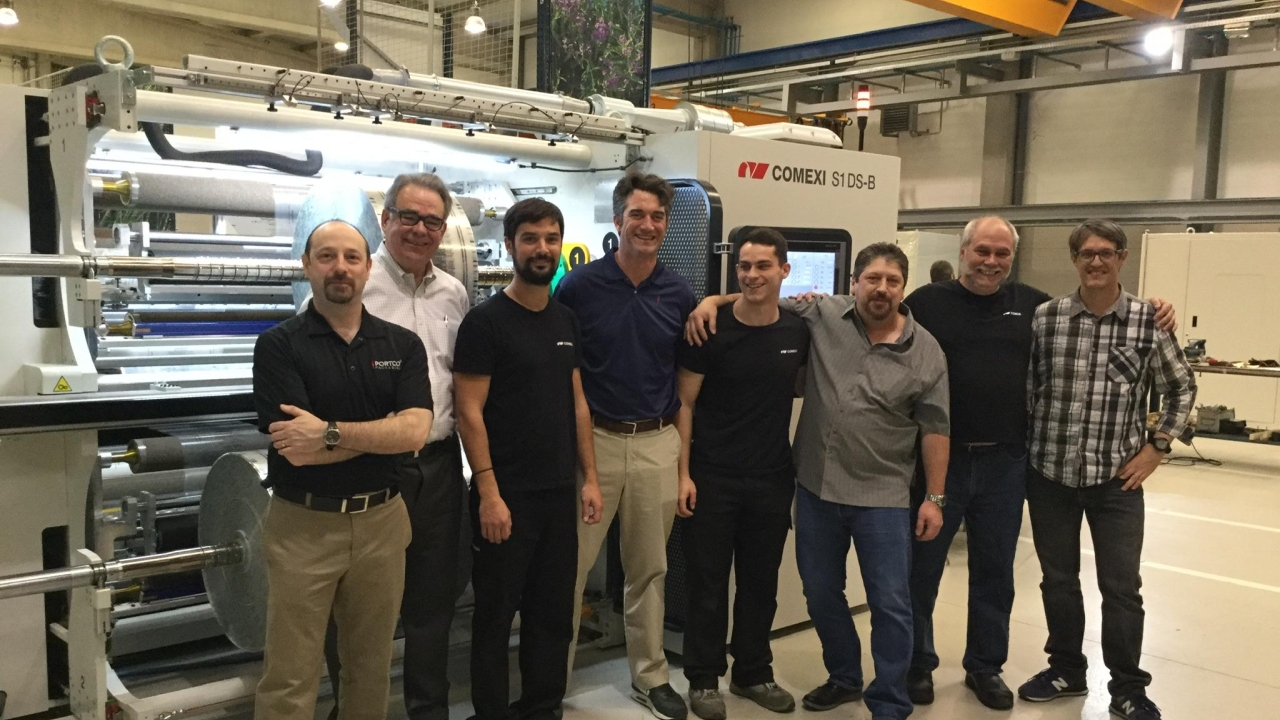

US flexible packaging printer Portco Packaging has installed a Comexi S1 DS slitter with integrated laser module.

Portco Packaging, a family-owned company for 85 years, is a supplier of high-end packaging for food, agriculture, construction and retail markets in the US. Founded in 1934, Portco manufactures paper and film-based packaging products. The company offers printed rollstock, laminations, multiwall bags and a variety of pre-made pouch styles. Its mission is to make the highest quality, safest flexible packaging in the most responsible way. In doing so, it is continuously developing new and better products, utilizing both solvent-based and solvent-free technologies as well as recyclable and biodegradable films.

The slitter with laser will be installed at Portco Packaging’s Southwest Washington facility and will allow it to work efficiently with large and small output diameters rolls with a cost-performance ratio that is especially attractive. Equipped with independent blades and shear cut sets, the slitter can handle a variety of challenges, as well as avoid oil spillage thanks to its fully electrical system. Recommended for work with large-diameter rolls, the acceleration ratios of the Comexi S1 DS achieve high productivity by rapidly reaching top speed without the loss of and can handle diverse challenges.

The integration of a laser-in-line processing system allows customization, differentiation and at the same time, performs a wide gamut of applications and finishing processes including: micro perforations, macro perforations, design windows, pre-cut adhesive labels, alphanumeric codes and barcodes, security systems and easy open applications.

Linda Malmstadt, vice president of sales and marketing at Portco Packaging, commented: ‘This new, one-of-a-kind technology from Comexi complements our existing capabilities and will enable us to provide a much wider range of packaging solutions for our customers. We are very excited about this addition and what it means for Portco's future.

‘The market for safe, easy to prepare pre-packaged foods is continuing to grow at a remarkable pace. Packaging technology plays a key role in this mix. From food packaging applications like easy open, microwave venting and extended shelf life, to soft security features such as numbering, promotions and bar/QR codes, this technology certainly addresses the current demands of the marketplace’

Kent Wall, president of Portco Packaging, said: ‘Comexi’s S1 DS slitter allows Portco to meet the future growing demands of our customers. Having an integrated solution from one supplier helps us ensure that we deliver a finished product that is extremely consistent and of the highest quality.’

This new technology will strengthen Portco’s position in the US flexible packaging market and provide it with a competitive advantage in the food packaging sector, according to Comexi.

Tom Calahan, Comexi area manager in this region, said: ‘Our integrated solution is a key selling point with many converters in this region. Sourcing slitting and laser equipment from a single source supplier, which can support both technologies, minimizes their potential risk.’

Rich Castillo, vice president of operations at Portco Packaging, added: ‘The integration of the laser system with Comexi world class slitting technology made the decision to work with Comexi on our project an easy one.’

Olof Buelens, vice president, Comexi North America, is excited about the continuous growth and partnership between Portco Packaging and the supplier, particularly because Comexi is introducing its latest technology pertaining to slitting systems. Currently, Comexi has several major ongoing investments in North America, including relocating its headquarters from Charlotte, North Carolina to Miami, Florida. This has expanded the company's operations and presence in the region. This new 15,000 sq ft facility will replicate the Technological Center Manel Xifra Boada (CTec) experience, currently at its European headquarters.

Further, this new demo and training center will give its customers an enhanced experience, in regard to printing, laminating and slitting within the flexible packaging industry, and will offer custom demonstrations.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.