Labor shortage: building an organization for lifetime employee

Label and packaging converters are facing a dramatic labor shortage, making continuous improvement strategies even more critical

The concept of a lifetime employee sounds antiquated as we read reports from the Bureau of Labor Statistics that the average worker changes jobs every four years.

The cost of losing an employee runs between $2,000 and $10,000 depending on the level of skill. A friend in his mid-50s attended a working symposium and learned he would likely have four more positions before retirement. A recent story in the New York Times underscored a study by Economist Nicholas Eberstadt, who identified nearly 7 million capable working men between the ages of 25 and 54 choosing not to work. The US Bureau of Labor Statistics reports civilian labor participation rates at 61.6 percent or, better said, the lowest rate since 1976.

It’s no wonder converters and suppliers in the label and packaging printing industry are complaining about finding new employees and their current employee retention. The deck seems stacked against traditional employers who still need to figure out a working environment that minimizes employee loss. We know that over the past two years, many companies aggressively implemented wage corrections addressing the number one complaint by employees. Pay alone does not address all the desirable traits an employee is looking for in an employer. We have an employment gap that will take years to resolve, and it is clear that converters are not only going to compete on growing their business levels, but they will also compete with each other on attracting employees.

Learn from the experienced

This workforce is getting older, with fewer individuals interested in this career. There is a significant gap in providing the opportunity for new printers to have proper time to learn from experienced ones. Pressures of throughput have shortened training, and there needs to be more formality to sharing, or the knowledge is soon to be lost. The common link is that in years gone by, crew leaders, supervisors and plant superintendents would work side by side with newer employees, listening to their expertise and then pulling together to solve the customer demand.

The companies with the best training have individuals on the print room floor who may be newer to the industry, but they share the stories of their company origin with their friends and peers as if they were there for years.

Finding magic in consistency

As I hear these stories from converters, I am searching for an elusive magic formula to help companies understand the best actions they can follow to fill their employment gap. It is essential to provide meaningful training experience so that employees will find contentment and fulfillment enough to work proudly at the company for a very long time. One leadership element is consistency. The notion that job satisfaction has little to do with the job but is more about providing an individual with personal fulfillment needs more attention.

Over the past two years, company employment policies and cultural norms rocked with change because of the pandemic. Many individuals are just now shaking off the impact of work restrictions, including travel and on-site working, with new policies many companies implemented to survive. Companies returning to a more normal state of employment are finding that changes are still occurring in the industry. Companies were bought and sold, and many older leaders began transition activities to next-level leaders. These actions can be unsettling and cause employees to consider what type of work experience, they are looking for. At the foundation, the company’s cultural norms need upgrading.

Operational focus is key

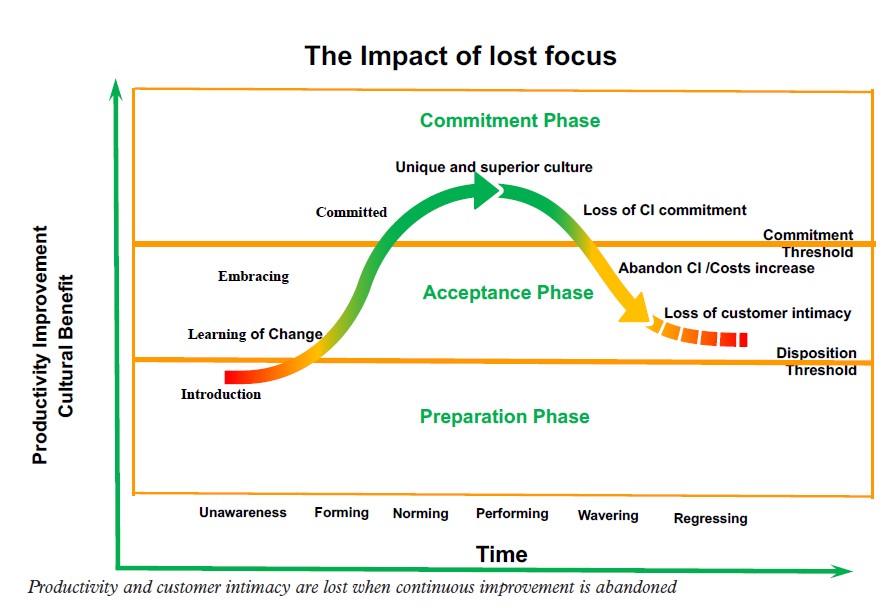

A common complaint from tenured employees is their leadership’s need for more focus, who often blame issues on outside influencers. Due to supply chain interruptions, leadership’s attention to lean manufacturing, ISO procedure and continuous improvement principles waned. These interruptions resulted in increased lead times, constant schedule changes and decreased productivity. Costly performance barriers have gone on too long because price increases passed on to customers hid the actual impact on the organization. Financial decline masked the importance of a company’s best practices, and the leaders need to clarify process disciplines. These actions allowed waste and increased time back into the business processes. The result, in some instances, has led to a catastrophic collapse of cultural gains not internalized by leadership. The economic climate has changed, and operational cost increases need resolution. Customers are starting to refute price increases and go out for bids based on the results.

Leaders who joined the executive ranks only in robust economic times, must prepare themselves for the toll on the organization and the action plans needed to reinvigorate their operational focus. The lack of experience managing an entire business cycle of highs and lows has challenged their ability to maintain cultural continuity, and they must now begin anew. Experienced leaders, seeing the gaps in execution, realize their succession planning must become more robust for the health of their company and their employees. Fortunately, the continuous demand for products provides the opportunity to set in motion actions that can regain momentum in company cultures stagnated by the events of the past few years.

As I work with the converters on renewing their commitment to continuous improvement, I reminded them that while the pandemic caused significant obstacles, the market segment remained robust. Equipment providers and consumable suppliers in the market fought their battles with supply chain issues. Many of them gave up on the continuous improvement focus, trying to survive the component shortages that plagued productivity. Some companies built inventories only to be stagnated by the missing final component that prevented shipment. This problem plagued just about every capital equipment industry. But the actions of prebuilding inevitably added costs and drained cash flows. The company’s reaction to the supply chain issues allowed process shortcuts and un-quality back into their operating systems.

A new normal

We are all dusting ourselves off from the calamity of the uncontrollable economic and pandemic events and find that we are now entering an economic cycle that will no longer accept price increases. Companies have to focus on cost containment. What if the thought process included the actions required to retain and attract employees? Leaders would have to determine the steps to restore commitments that foster productivity improvement, cultural involvement and accountability to flourish robustly in the market segment. Strategic plans placed on hold would be set in motion for rapid execution so that the employees could quickly see some benefit from their involvement. Two years ago, we talked about pay being the most significant obstacle to employee retention, and the business owners in the industry responded. Today a company’s leadership is tested again for their fortitude in sustaining a cultural environment that demonstrates attractiveness for the next generation workforce. What employees are asking now is: ‘are the next generation leaders committed to a culture of improvement, and do they have the stamina to stay

the course?’

Several leaders have asked me to communicate a path forward that will ignite change. Subject matter experts

who were my mentors always emphasized that a company must renew its commitment to improvement every three years and find the catalyst that will force the issue. The best foot forward is ensuring the executive team is the catalyst. Holistically they have to embrace their commitment and rally together as an unwavering force, often revisiting actions they already know but have lacked the discipline to sustain. The group needs to start again learning the behaviors they must outwardly demonstrate each day. As a team, they should begin reading material pertinent to the focus. They should select the reading material and discuss their readings as a group.

Next, I recommend they dissect metrics that highlight fundamental process problems, discuss what needs to change, and then identify and commit to aggressive, quick-hit actions that benefit quickly. I provide a reading list of critical materials, including books like “The Gold Mine” by Freddie and Michael Balle or “Lean Thinking” by Womack and Jones.

Real-world examples

Some forward-thinking companies have designed and implemented continuous improvement certification plans for their employees to foster engagement. One such program is called the Bronze Certification Plan, which includes a list of books required to be read, complete with a simple write-up indicating the best takeaways from the reading. The certification process consists of a list of four to six more tasks plus participation in at least two kaizen events followed by actually leading an event. The certification is awarded when the criteria are verified. Additionally, the employee participates in a leadership communication and planning session for their career in the future. In this example, employees who completed certification become advocates rewarded with a slight pay bump as recognition of their commitment. Larger organizations have formed Lean Promotion Offices, where they set aside office space for a library dedicated to education about lean manufacturing. They equip the library with several books that the employee can check out. In addition, they have created company stores with promotional items promoting the production system commitment and have assigned an executive leader to organize kaizen teams based on feedback from the metrics and organizational leaders.

The most important takeaway I emphasize is that outside forces will constantly challenge an organization. The most successful organizations continuously learn to shift with the market changes. No one can predict all of the hurdles a company will face, but the best leaders act on securing the best assets for the company in people. Leaders that wavered on process disciplines thinking process shortcuts could help weather the trying times are now seeing that had they held on to their convictions, their employment culture would be much healthier now. These leaders will become invaluable to the company if it truly is a lesson learned. If nothing was learned, they will repeat the mistake and create a less-than-desirable workplace. Find those companies, and you will find employees looking for a better workplace.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.