★You are viewing this content as a subscriber

★Subscribers only

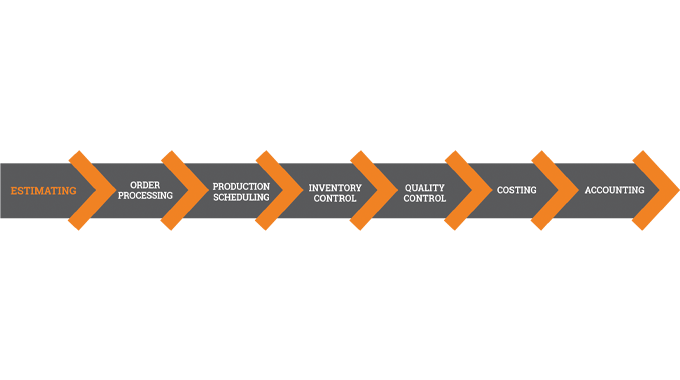

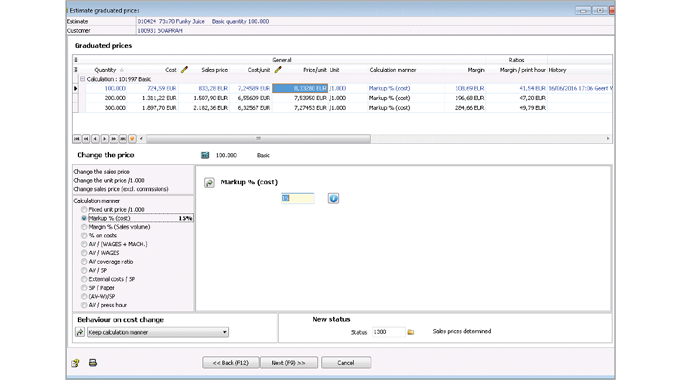

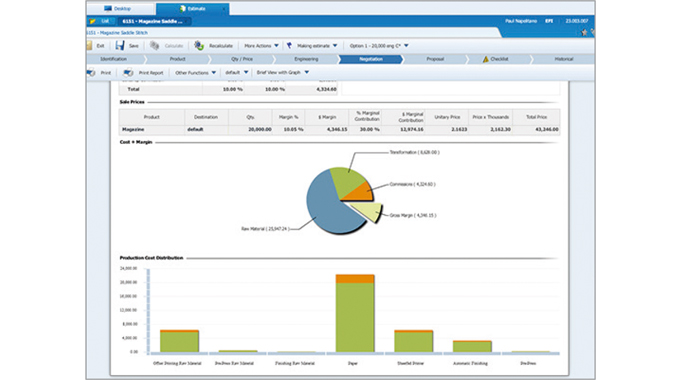

Estimating for label and package printing

Accurate estimating is at the heart of every successful label or package printing operation

Accurate estimating is at the heart of every successful label or package printing operation. After, all, one of the first things a prospective customer wants to know is how much is the job going to cost. Get it right and the company will make an acceptable profit on each job produced. Get it wrong and the company may regularly lose work or make a loss on the job they have produced.

As a consequence, they can soon fall into a loss making situation.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.