★You are viewing this content as a subscriber

★Subscribers only

Inks, coatings and varnishes – safety explored

Without ink it is not possible to reveal what is inside a pack, instructions regarding usage and of course who made the product

Ink is, of course, an indispensable component of any label or packaging application. Without ink it is not possible to reveal what is inside a pack, instructions regarding usage and of course who made the product. A blank label is essentially useless.

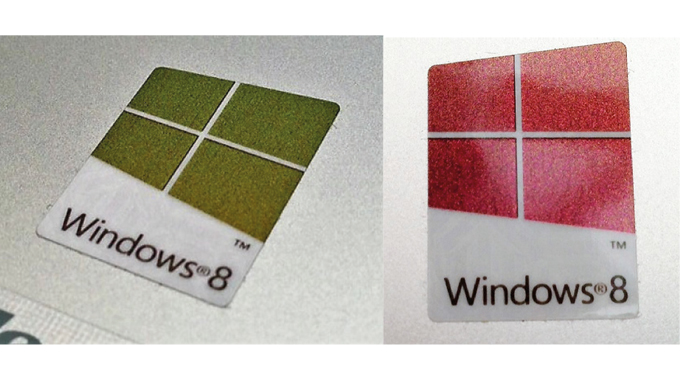

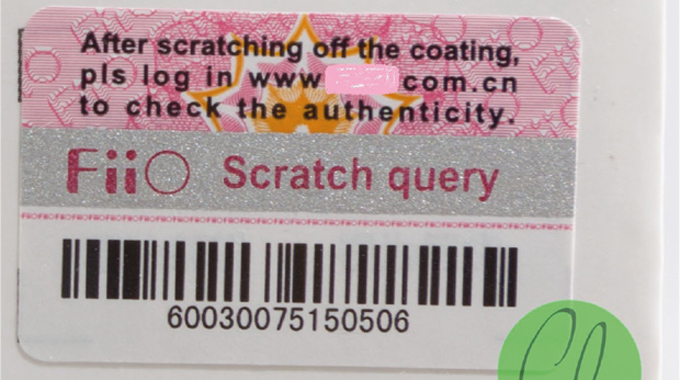

Since ink is used to open a visual communications channel between every party in the process of product distribution and final use it follows that it can also offer a handy method of communicating provenance at the same time.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.