★You are viewing this content as a subscriber

★Subscribers only

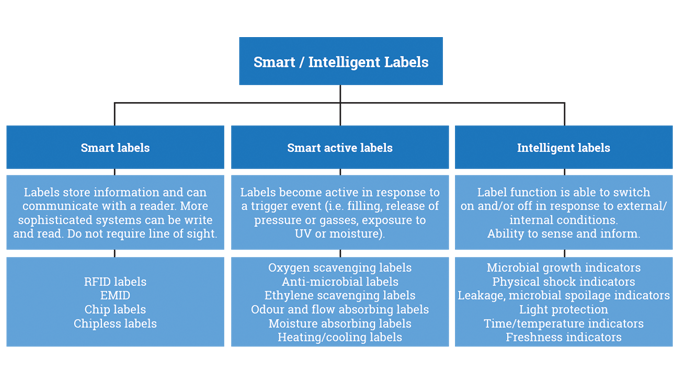

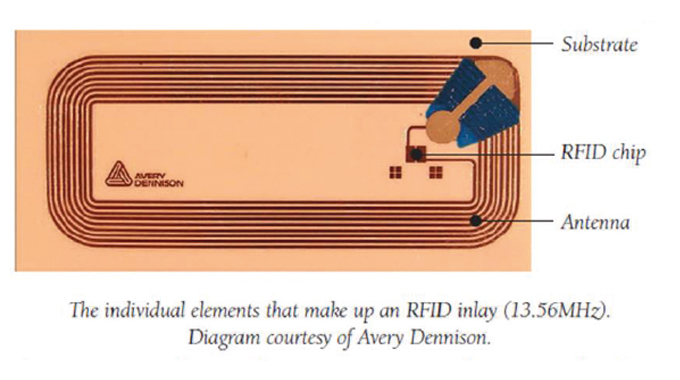

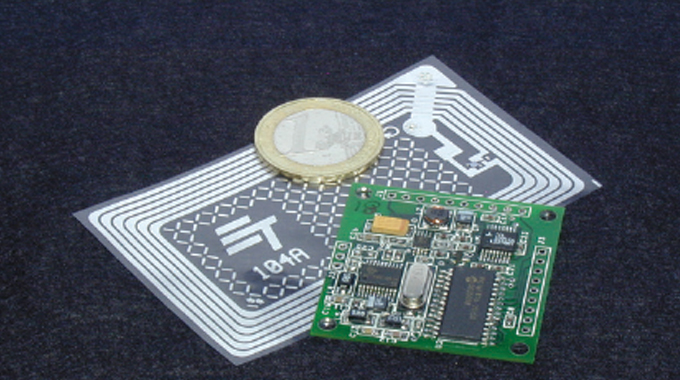

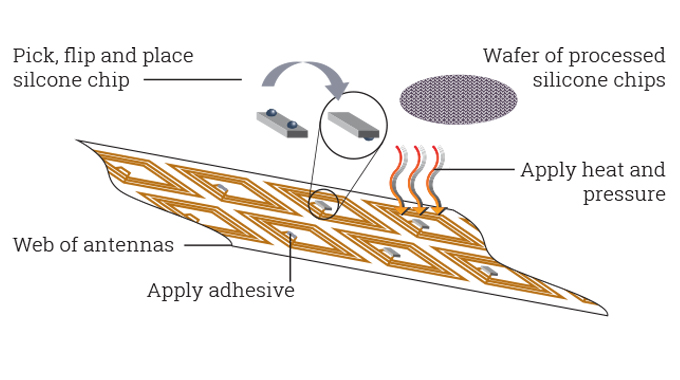

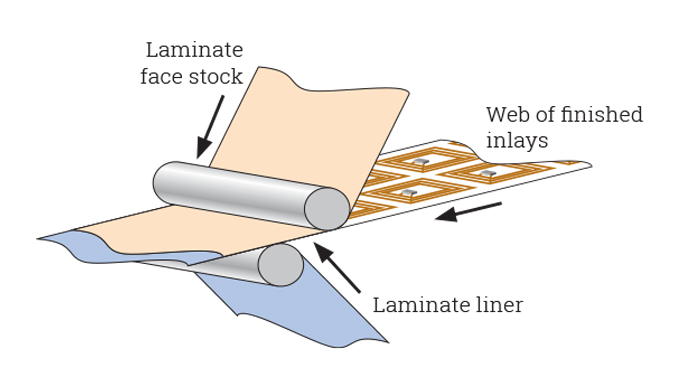

Smart, active and intelligent labeling

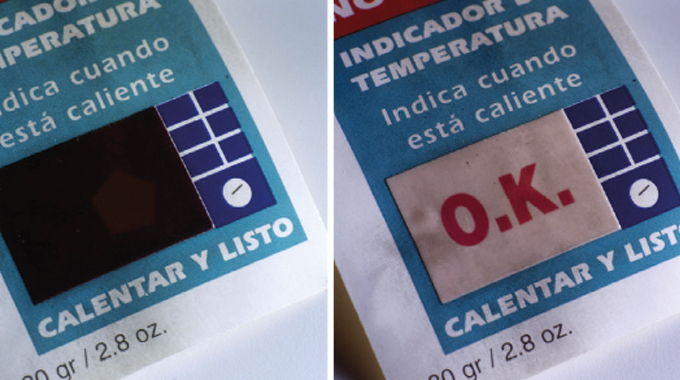

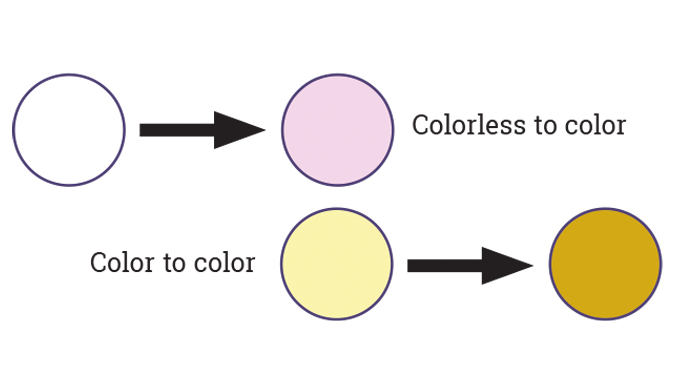

Interest in materials that react to environmental conditions such as light, heat, gases, pH and moisture is gathering pace

The focus of this article has been primarily on processes and techniques that are able to enhance the visual appeal of the label.

New technologies are emerging however, that are extending the role of the label beyond that of the purely aesthetic and into one that is much more functional.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.