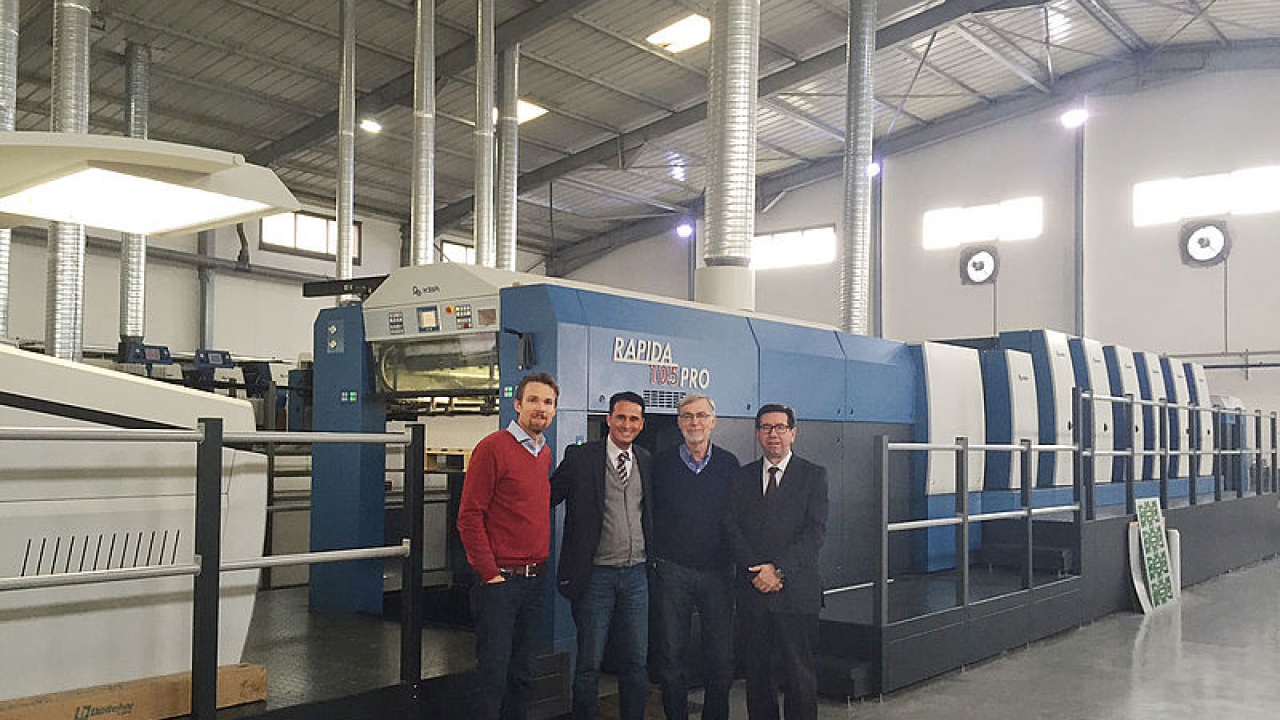

African printer installs KBA Rapida 105 Pro

Morocco’s Fleximat has installed a KBA Rapida 105 Pro to secure a competitive lead in packaging printing.

The six-color coater press stands on 450mm raised foundations to accommodate the higher piles that are typical in packaging printing, and is now producing alongside two further Rapidas in the recently built print center in Mohammedia, approximately 40km from Casablanca.

Abdelaziz Benchekroun, president of Fleximat, said: ‘The market launch of this new press came at the perfect time for us. Our decision in favour of the Rapida 105 Pro was carried by the confidence that, even without exceeding our investment budget, we would be able to incorporate a number of interesting technical solutions, which are otherwise only available in the highly automated Rapida 106.’

KBA described the emerging North African markets as being characterised by high price sensitivity. As economic prosperity increases, fixed costs increase to a similar extent – and print production is here no exception. When planning long-term investments like a printing press, the technical features and automation must secure competitiveness not only today, but also in the foreseeable future. As a leading packaging producer in Morocco, Fleximat places a strong focus on customer service in both gravure and offset printing. To escape price pressures, the management is careful to ensure that any new investments strengthen the technological lead over other companies.

Fleximat CEO Mehdi Benchekroun commented: ‘It was against this background that we chose to integrate fully automatic plate changing, facilities for non-stop pile changing at the feeder and delivery, and the energy-saving VariDryBlue dryer technology, for example.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.