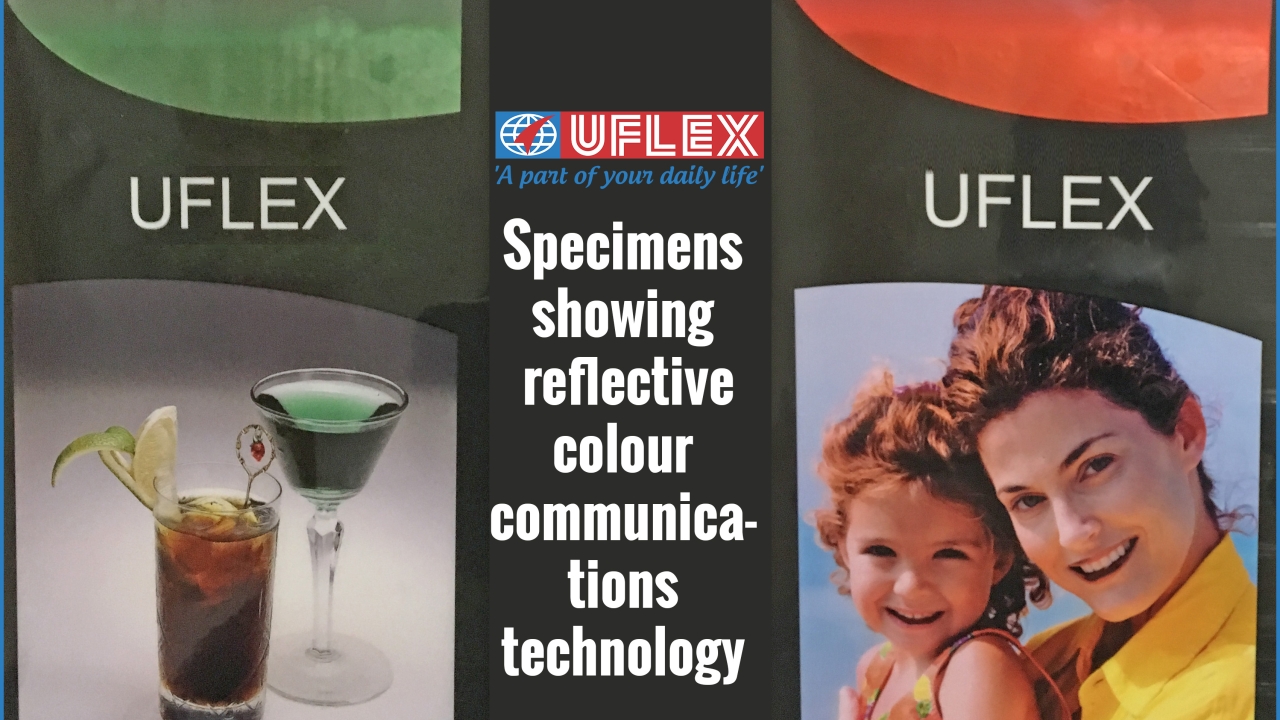

Uflex develops reflective color communications system

Uflex has developed Reflective Color Communications, a system that achieves metallic effects on non-metallic substrates without using metalized inks.

The cylinders division of the company attained a metallic effect on non-metallic substrates by manufacturing a special rotogravure cylinder that uses normal transparent gold or transparent silver inks or lacquer inks. This effect is achieved by reflective color communication technology that works in combination with a specialised pre-press software and laser engraving hardware. The customized software ensures that the dots are precisely distributed throughout the design so as to produce a homogeneous metallic effect. Getting the same effect through specialized metallic inks can make conversion costs high. Further benefits of this technology include reduction of laminate cost to the end customer, while converters and brands will benefit with a metallic sheen on a two-ply laminate instead of three or more substrates, as long as a barrier layer is not compulsorily required by the product to be packed.

This metallic effect is manufactured as a half tone image. If the white printing cylinder is eliminated, this arrangement translates to much less ink consumption.

In addition, these cylinders work on the existing printing machines and make it an economical technology for augmenting a brand’s shelf appeal without the use of metallic inks. This technology is adaptable for future substrates, inks and coatings.

P K Agarwal, joint president of the cylinders business at Uflex said: ‘This technology is a real shot in the arm for convertors and helps them add value for their clients by enhancing the aesthetics of their packaging without using prohibitive metallic inks or metallic laminate. We are getting many enquiries for the special printing cylinder.’

Ashok Chaturvedi, chairman and managing director of Uflex, added: ‘Such progressive value addition throughout the chain eventually results in an aesthetically unique and functionally superior packaging. The packaging and converting business vertical at Uflex has already tried and tested this technology which makes us confident to offer it to converters outside Uflex.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.