Understanding metrics

The market pressure on converters in label and packaging printing has long impacted the course of action being taken by their owners. For many of the small and middle-size converters, understanding where they are concerning the competitors seems an ominous undertaking as the larger firms and private equity-backed groups seem to be advancing with technology investments that can outpace traditional legacy equipment or the smaller organizations. I am, however, reminded of the annual label awards throughout the world, often being won with legacy equipment by smaller converters.

If employees are not engaged, then all technology investments will fall short of expected returns

Today the technologically advanced converters are faced with the same problems as the less technology-capable. The competitive landscape is evened by the most important asset they have: their people. If employees are not engaged, then all technology investments will fall short of expected returns.

Recent reports from major economic and business magazines are discussing post-pandemic trends, including that 25-40 percent of employees are thinking about quitting their job. To avoid this trend, employers must develop their company culture so that it encourages an individual to stay and become engaged, and then facilitate a feeling of accomplishment.

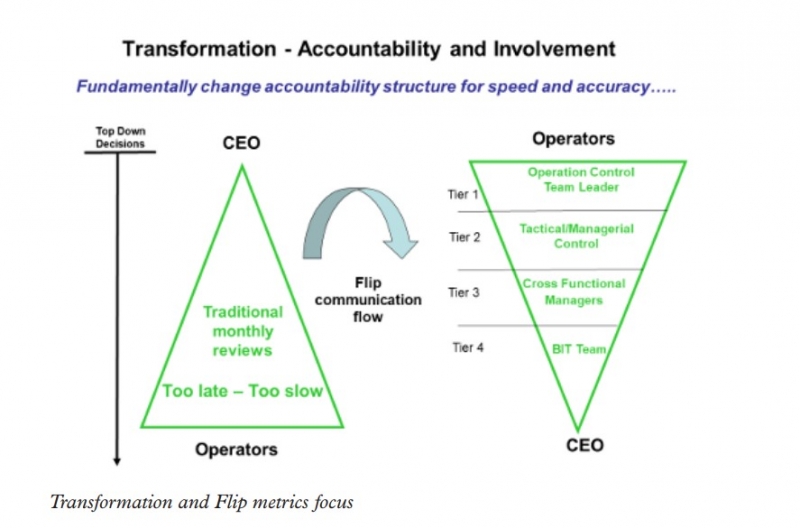

Fostering this cultural awakening starts with talking about the right things at the right time. The shift in communication includes a focus on metrics at the source that are meaningful to the operators and can be directly impacted by their actions. Additionally, the old saying ‘We pay our people competitively’ really means you are paying averagely. Leading organizations understand that competitiveness is also about company culture.

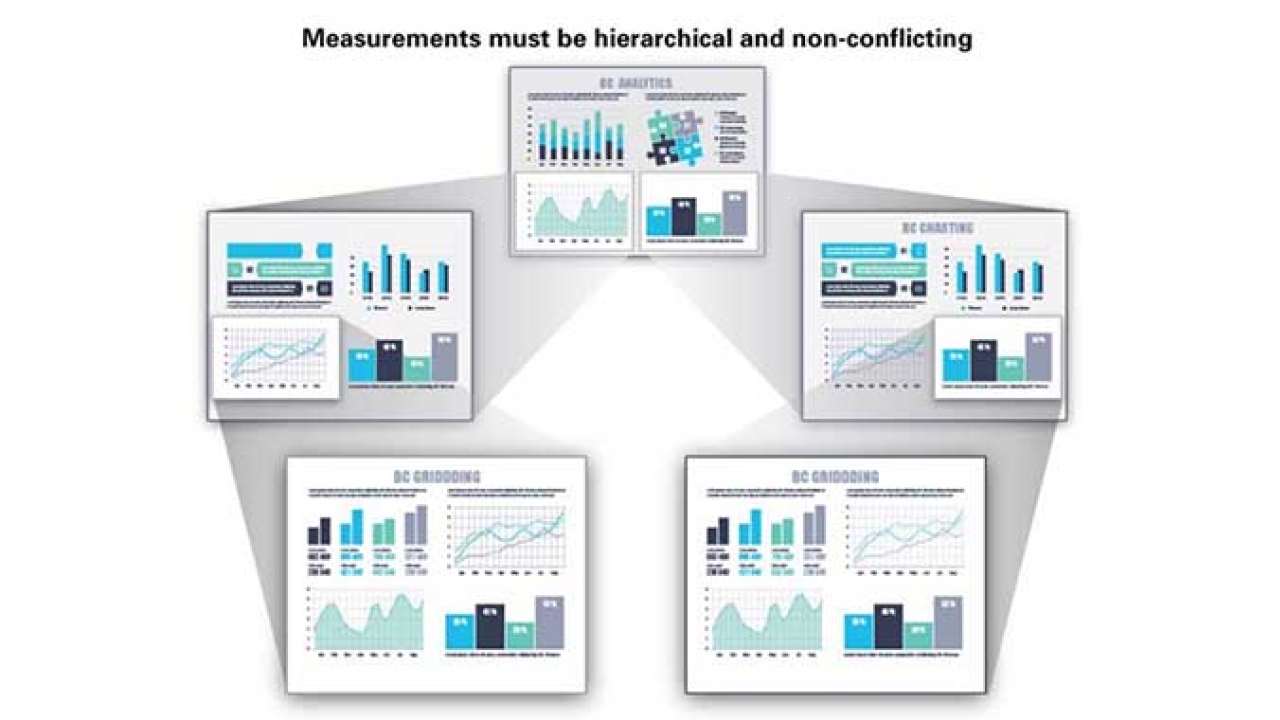

This puts more pressure on leaders to build an engaging culture.They have to fully understand market variables that impact overall financial performance and then understand the correlation of operational activities and their impact on the financial performance. A key element of leadership is setting the direction for the organization and then building strategies and action plans to advance it. I can speak to this process from my own experiences, and because I’ve visited dozens of printing facilities and have seen first-hand what ‘excellence’ is all about. It starts with aligned leadership balanced with a focus on hierarchical process-driven metrics. This asset investment tops any equipment investment.

Philosophical or cultural changes in an organization need a catalyst. Sometimes that catalyst must come from outside the group, from someone who can work, hand in hand, educating leadership. The fortunate organization finds the internal champion who has learned the correct values, rules and procedures and can become the influencer a senior executive can rely on to help with fundamental changes and help teach others to take action. Even better is if that champion is a member of the executive staff. Advancing as change agents, leaders must understand organizations will go through various phases of adoption on the path to internalizing the change.

Therefore, the organization will require preparation including education and communication of the need to change.

Learning organizations have typically established libraries of information and made it readily available on the company’s shared drive. Others have established a Lean Promotion Office (LPO) reporting directly to the COO or CEO. In these early stages of implementation, organizations are often met with resistance to change due to unawareness, confusion, and the negative connotations associated with change. Important to this transition is being able to explain what winning looks like.

Financially focused individuals would say: It is easy, the goal is to make an improved profit. That sort of thought process does not resonate on the production floor or in the order entry department. The communication has to be about something the operator can impact.

Fundamentally these metrics are cycle time, quality (First Pass Yield), and productivity. The lack of understanding of this requirement is exactly why organizations slide back into old routines or why improvement initiatives stall.

You must have aligned metrics

Earlier in my career as a middle manager and an evangelist for continuous improvement, I struggled when the financial performance of the company was shared with employees at quarterly meetings. It wasn’t that I was not interested in the company’s health; rather in these meetings we always heard about falling short of financial expectations when it was too late to impact the outcome. Often, we were confused as to the viability of the improvement projects we were working on and their direct benefit to the financial performance. We could not tie our actions to the results. What I discovered when moving from a shop floor focus of improvement initiatives to an overall company focus was that the linkage between functioning groups was disconnected. What was important in one department may have negatively

impacted performance in another department based on the way we were measuring.

When focused on the drivers impacting time, converters were able to reduce cycle time by 35 percent within three months

The best metrics are developed with the help of the operators and stimulate activity by the operators, work cell leaders, supervisors and support staff. An organization must separate reported metrics as ‘results’ from the immediate information an operator needs to ‘drive’ action – impacting the performance in real-time, during the production run.

Much of this confusion is further ironed out when we fully understand a focus on process drivers. Driving metrics are leading indicators to results metrics. A driver metric is time-based, waste-based, quality-based or productivity-based. Time is one of the most important measures to driving improvement. Think about this in any department – the cycle time it takes to complete a process step. Job changeover time, customer response time, time to get problem resolution, waiting time caused by interruptions or lack of information – all these impact time to market.

If you can reduce the time, you inherently focus on improving quality and reducing costs, leading to improved service. In the production world, managers and operators may have heard the term OEE (Operational Equipment Effectiveness). Fundamental to this measure are time and quality. Time is also a great driving metric for nonproduction departments.

Converters I have visited and helped have reported waiting three or more days for correct order data from the sales department or from the customer just to process an order into the management system. Sometimes this delay was the fault of the salesman and sometimes of the customer. The impact is the same.

Waiting adds to cycle times, missed shipment promises, and expedites on the production floor. Internally the process could not start because of a lack of information or incorrect information. The customer does not understand this or rarely cares: they just need the product.

I found this single issue in over a third of production orders I examined. Everyone in the organization knows the delay causes havoc because it leads to schedule interruptions with ‘expedites’ which, simply stated, is a substitute process. The better course of action is to hold the order and not release it to the floor, help the sales team understand the impact of the lack of information, and help the customer understand they can speed response by providing correct information up front.

When focused on the drivers impacting time, converters were able to reduce cycle time by 35 percent within three months. In these examples, all customers benefited. And in this industry when the customer is educated and participating with the organization, they typically become a customer for life.

Simple and visual

Evolving a workforce around driving metrics is facilitated by making those metrics simple and visual. While technology has advantages, we’ve learned that when an operator has to track and post key metrics manually, they become more personal and important. This is also one of the primary reasons the operators in every department have to be involved in defining how a metric is scored. Something as simple as ‘on time’ has to be clearly defined at the operator level. Key driving metrics could include uptime, downtime, counts, speed, changeover time, interruptions. Simple tracking on the floor at the work center becomes a communication hub for the operators and the support staff. The metric focus is further enhanced by aligning each level of the organization to the drivers selected.

The best driving metrics:

• Improve as the underlying process improves

• Worsen as the underlying process worsens

• Are viscerally meaningful to the operator

• Are applied consistently in similar situations within

the company

• Drive correct behavior

• Deliver a justifiable benefit/expense ratio

• Benefit the customer and help make the customer competitive

Transformation with simple visual metrics will fundamentally change the accountability structure in the company.

Being visual is more than posting metrics at defined locations on the production floor. The metric review at the work cell level, usually reviewed at least in two-hour intervals and called the Tier 1 meeting, hones the conversation for the operator and their immediate group or cell leader. Having the metrics visual helps drive focus on self-explaining, self-cleaning, self-improving and self-regulating. Everyone immediately knows the current status and problems. More important is the capability to immediately identify the cause and assign resources to help fix any performance deficiency.

At the start of the shift, the work cell boards are reviewed and handed off from one shift operator to another, keeping the momentum of the production run and making sure important conversations are held with details of equipment performance, special instructions and interruptions.

Additionally there is usually a round-up for the day when a supervisor may choose to hold a kick-off meeting with a larger workgroup. These meetings, typically 10 minutes in length, are referred to as Tier 2 and focus on a round-up of a defined workgroup around Safety, Quality, Delivery, Interruptions, Productivity (SQDIP). Because these visual metrics are local and simple, they make the perfect backdrop for conversation when leadership completes their weekly or daily GEMBA (Go and see) walk.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.