Labelexpo Americas 2022: A-Z technology preview

Actega showcases its specialty and haptic coating effects for labels and shrink sleeves along with live presentation of its EcoLeaf metallization technology on the ABG stand. EcoLeaf eliminates the need for foil and reducing the carbon footprint of metal pigment finishing by 50 percent.

Actega showcases its specialty and haptic coating effects for labels and shrink sleeves along with live presentation of its EcoLeaf metallization technology on the ABG stand. EcoLeaf eliminates the need for foil and reducing the carbon footprint of metal pigment finishing by 50 percent. Copies of the 2022 Q3 issue of Converting Quarterly, AIMCAL’s official technical journal, along with our AIMCAL-TLMI jointly produced Special Report on Labeling & Release Liners, are also available. Print and digital-edition subscription information and guidelines for contributing a technical paper to the magazine are included.

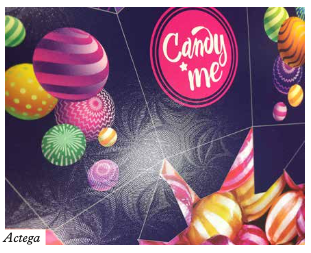

This Twin Track approach offers several significant advantages. All parts of a cell can be reached by the focused laser beam, and the power of each of these points can be controlled. According to the company, the Energy Density Ceiling is no longer an issue because Twin Track operates close to sharp focus. Twin Track enables allows users to achieve higher cell volumes with a lower depth of engraving, thanks to the focused laser beam moved around the anilox cells with the laser power changed dynamically to keep the cell bottom flatter.

This Twin Track approach offers several significant advantages. All parts of a cell can be reached by the focused laser beam, and the power of each of these points can be controlled. According to the company, the Energy Density Ceiling is no longer an issue because Twin Track operates close to sharp focus. Twin Track enables allows users to achieve higher cell volumes with a lower depth of engraving, thanks to the focused laser beam moved around the anilox cells with the laser power changed dynamically to keep the cell bottom flatter. Applied Rigaku Technologies presents NEX LS, an in-line silicone coating analyzer for real-time process control. NEX LS software provides a clear visual representation of the process. Its analytical head sweeps back and forth across a moving web and real-time data displays as a graphical crossdirection and machine direction profile. The company also offers at-line benchtop unit for measuring very low silicone coating weights and metal catalysts in silicone coatings. Both benchtop and process solutions feature EDXRF (energy dispersive X-ray fluorescence) technology, a standard, nondestructive technique used in the paper and film industry for determining silicone coating thickness and composition.

Applied Rigaku Technologies presents NEX LS, an in-line silicone coating analyzer for real-time process control. NEX LS software provides a clear visual representation of the process. Its analytical head sweeps back and forth across a moving web and real-time data displays as a graphical crossdirection and machine direction profile. The company also offers at-line benchtop unit for measuring very low silicone coating weights and metal catalysts in silicone coatings. Both benchtop and process solutions feature EDXRF (energy dispersive X-ray fluorescence) technology, a standard, nondestructive technique used in the paper and film industry for determining silicone coating thickness and composition.  Arrow Systems showcases the latest water-based pigment inkjet using the Duraflex technology from Memjet, the ArrowJet Aqua 330, designed to print labels, flexible packaging, blister foils and shrink sleeve materials using water-based pigment inks. It can operate at 1600x1600 DPI and speeds of up to 150ft/min. In addition to the high-speed inkjet products, Arrow Systems promotes a wide range of digital finishers and in-line products for printing and cutting in a single pass. The company showcases blade and laser finishers with the latest for in-line print and cut technology, the ArrowJet Nova 330R.

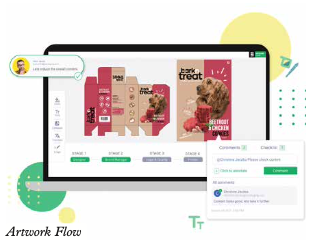

Arrow Systems showcases the latest water-based pigment inkjet using the Duraflex technology from Memjet, the ArrowJet Aqua 330, designed to print labels, flexible packaging, blister foils and shrink sleeve materials using water-based pigment inks. It can operate at 1600x1600 DPI and speeds of up to 150ft/min. In addition to the high-speed inkjet products, Arrow Systems promotes a wide range of digital finishers and in-line products for printing and cutting in a single pass. The company showcases blade and laser finishers with the latest for in-line print and cut technology, the ArrowJet Nova 330R. Artwork Flow presents its flexible workflow management system for multi-stage approval and artwork collaboration. Additionally, the company features an AI-enabled Smart Proofing for FDA compliance, helping brands go to market faster. Visitors are able to learn how the platform helps pharmaceutical and life sciences brands with efficient 21 CFR Part 11 compliance.

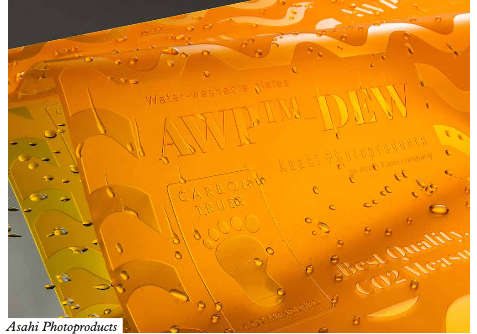

Artwork Flow presents its flexible workflow management system for multi-stage approval and artwork collaboration. Additionally, the company features an AI-enabled Smart Proofing for FDA compliance, helping brands go to market faster. Visitors are able to learn how the platform helps pharmaceutical and life sciences brands with efficient 21 CFR Part 11 compliance. Asahi Photoproducts features its AWP-CleanPrint line of water-washable flexographic plates designed as more sustainable alternative for traditional solvent-washable plates and to deliver improved quality on press with reduced cycle time.

Asahi Photoproducts features its AWP-CleanPrint line of water-washable flexographic plates designed as more sustainable alternative for traditional solvent-washable plates and to deliver improved quality on press with reduced cycle time.The company is also showcasing its portfolio of slitting and rewinding equipment, including Opal ISR, full 100 percent inspection slitter rewinders; Opal EC, entry-level model label inspection slitter rewinders; Opal ILT, in-line turret rewinders; Opal LCL, full rotary label converting lines; Opal ALCL, full rotary label converting lines with automatic turret rewinders, and Solitaire, mid-web duplex slitter rewinder for shrink films, wraparound labels and flexible packaging.

Ashe is also promoting the range of wide web slitter rewinders for converters of pressure sensitive products and flexible packaging.

The company showcases the Automatic SAMM 2.0 800, the next generation automatic mounting machine for the flexo narrow-web industry. SAMM 2.0 flexo plate mounter is said to automatically mount a flexo plate in less than one minute with accuracy, repeatability and speed. Live demonstrations of the SAMM 2.0 800 are shown at the exhibition.

Meeting ongoing customer demand, Baldwin is launching the Guardian PQV 100 percent print inspection version 4.0, designed and manufactured to help printers achieve print quality and reduce material waste.

These state-of-the-art camera systems can provide single or dual sided 100 percent print quality inspection for any application, ranging from high-volume label production with variable data to inspecting the challenging security print applications with features such as UV fluorescent, fiber inspection, IR covert, optically variable devices and inks, and magnetic inks.

The Guardian PQV is designed for ease of use, reducing the need for operator training and minimizing the problem of press staff turnover.

Visitors to Baldwin’s booth can also find products from its Vision Systems segment, comprising the advanced color management and inspection technology. Baldwin Vision Systems print inspection and defect tracking workflows help to eliminate defects from outgoing products, providing quality to brand owners.

Berhalter presents a new Swiss Die-Cutter B6, delivering 500 strokes per minute. The machine digitally die-cuts with maximum precision, featuring individually controlled die-cutting motion, flexibly adjustable opening level of the punching tool, digitally monitored penetration depth and a new active foil guide built into the punching tool.

Berhalter presents a new Swiss Die-Cutter B6, delivering 500 strokes per minute. The machine digitally die-cuts with maximum precision, featuring individually controlled die-cutting motion, flexibly adjustable opening level of the punching tool, digitally monitored penetration depth and a new active foil guide built into the punching tool. Cartes showcases the Cartes Jet D-Screen digital embellishment system combined with the company’s laser die-cutting system. The Jet D-Screen module is designed to create labels with multilayer effects, spot coating, complex tactile effects, braille printing, and detailed foiling and metallic doming.

Cartes showcases the Cartes Jet D-Screen digital embellishment system combined with the company’s laser die-cutting system. The Jet D-Screen module is designed to create labels with multilayer effects, spot coating, complex tactile effects, braille printing, and detailed foiling and metallic doming.With a service temperature range from -65° F to 147° F and a minimum application temperature of -8° F, Frost AT is suitable for extremely hot and cold label applications and application environments. Additionally, it offers excellent adhesion to polyolefin and paper substrates. Frost AT reduces label peel in the most challenging label applications while also performing well at room temperature.

Colordyne Technologies introduces the 3800 Series WB (water base), a sustainable water-based inkjet engine utilizing a Kyocera mechanical piezo printhead technology ideal for food packaging and pharmaceutical packaging.

Colordyne Technologies introduces the 3800 Series WB (water base), a sustainable water-based inkjet engine utilizing a Kyocera mechanical piezo printhead technology ideal for food packaging and pharmaceutical packaging. Showcasing the advancements of high-speed microscopic flexo security printing – utilizing high-definition inks from Cyngient and enhanced resolution printing plates from Imageworx – Labelexpo attendees will be able to view new ultra-fine lines printed in decorative, intricate, and precise patterns. These security labels hold line weights below 5 microns in thickness, plus positive type printing as low as 0.3 pt and reverse type at 0.4 pt on a 1200x microscope.

Also, at the show, Cyngient and Imageworx showcase an accumulation of various high-security in-line flexo additions. On display will be Liquid Silver Flip, shapeshifting cold foil technology from Wavefront Technologies, and Lumachrome, a color-shifting security foil from Meta Materials that features triple-layered micro-motion barrier effects, iridescent security varnish, and plasmonic metamaterial arrays.

In addition, Labelexpo attendees can witness the latest advancements in Micro Optical Array printing for brand protection labeling.

Dantex Group launches its next generation of digital inkjet technology.

Dantex Group launches its next generation of digital inkjet technology. Daco Solutions together with its partner Flexo Export, exhibits a Daco PLR350 slitter rewinder with a three-spindle semi-automatic turret rewinder. The patented PLR is available with web widths of 250mm (10in), 350mm (13.75in) and 430mm (17in). The machine is available with inspection table, vision system and rotary die station for plain label production and a large capacity unwind to keep roll changes to a minimum.

Daco Solutions together with its partner Flexo Export, exhibits a Daco PLR350 slitter rewinder with a three-spindle semi-automatic turret rewinder. The patented PLR is available with web widths of 250mm (10in), 350mm (13.75in) and 430mm (17in). The machine is available with inspection table, vision system and rotary die station for plain label production and a large capacity unwind to keep roll changes to a minimum.  Dip Co demonstrates its quick change flexo pan liner technology developed for digital and in-line press equipment. The company also promotes its line of bio-friendly, non-conductive ink pan liner and catch tray inserts spanning all segments of the print industry. Products support all inks and coatings, from water-based to UV, and are solvent safe.

Dip Co demonstrates its quick change flexo pan liner technology developed for digital and in-line press equipment. The company also promotes its line of bio-friendly, non-conductive ink pan liner and catch tray inserts spanning all segments of the print industry. Products support all inks and coatings, from water-based to UV, and are solvent safe. Domino debuts its N730i digital UV inkjet label press and showcases its N610i and K600i in booth 6523.

Domino debuts its N730i digital UV inkjet label press and showcases its N610i and K600i in booth 6523. DPR Labeling debuts two new roll-to-roll digital converting machines for mid to high-volume label production.The Taurus laser finishing system operates at speeds up to 30m/min. Eliminating the need for conventional die plates, this high-speed laser system has the power to produce any shape on rolls up to 350mm (13.8in) wide. Capable of laminating, cutting, slitting, removing matrix, and rewinding, this all-in-one system allows users to customize jobs and deliver on demand.

DPR Labeling debuts two new roll-to-roll digital converting machines for mid to high-volume label production.The Taurus laser finishing system operates at speeds up to 30m/min. Eliminating the need for conventional die plates, this high-speed laser system has the power to produce any shape on rolls up to 350mm (13.8in) wide. Capable of laminating, cutting, slitting, removing matrix, and rewinding, this all-in-one system allows users to customize jobs and deliver on demand. Visitors can learn more about Cyrel Fast, a thermal platemaking system that consists of a thermal processor and a large variety of photopolymer printing plates for flexible packaging, labels and other applications.

The company also promotes the award-winning DuPont Cyrel Lightning plates delivering productivity and quality. The new plate family is optimized for UV-LED exposure units to use this system’s capabilities fully. The benefits of the plates include a further optimized match between access time and plate performance without compromising print quality.

Durst Group showcases its Tau RSC printer series. New features increase the productivity of the flagship printer, the Tau RSCi, with a print width of up to 20in and a print speed of 328 ft/min, and this will be shown for the first time at a trade show. Customers can also experience the power of the Durst Workflow Label and how intelligent software helps reduce ink consumption.

Durst Group showcases its Tau RSC printer series. New features increase the productivity of the flagship printer, the Tau RSCi, with a print width of up to 20in and a print speed of 328 ft/min, and this will be shown for the first time at a trade show. Customers can also experience the power of the Durst Workflow Label and how intelligent software helps reduce ink consumption. Eaglewood Technologies introduces the Sitexco Label L10 anilox cleaning system, based on the award-winning Sitexco laser anilox system. The L10 is a slimmed-down version especially designed for narrow web printers. This technology does not require chemicals or water and doesn’t generate waste.

Eaglewood Technologies introduces the Sitexco Label L10 anilox cleaning system, based on the award-winning Sitexco laser anilox system. The L10 is a slimmed-down version especially designed for narrow web printers. This technology does not require chemicals or water and doesn’t generate waste. Epson showcases the SurePress L-6534VW UV press available with digital varnish or orange ink. The digital varnish offers spot varnish, simulated foiling, and embossing, all in-line with label production. Orange ink has a 92 percent Pantone coverage certification within Delta E of 1.5. The L-6534VW models automates maintenance and checking of the printheads during the production day without operator intervention.

Epson showcases the SurePress L-6534VW UV press available with digital varnish or orange ink. The digital varnish offers spot varnish, simulated foiling, and embossing, all in-line with label production. Orange ink has a 92 percent Pantone coverage certification within Delta E of 1.5. The L-6534VW models automates maintenance and checking of the printheads during the production day without operator intervention.The company showcases innovations in ArtPro+ including printing unit support and repeat layout creation, as well as folding carton improvements, a new usage dashboard, and enhanced WebCenter usability features improving ease of use and maximizing productivity and efficiency.

At the heart of the Esko booth, the CDI Crystal 4260 XPS, in combination with the new Flexo Engine module, demonstrates how digitization in flexo production also boosts efficiency while delivering the best quality plates.

Underlining the benefit of automated processes, Esko also demonstrates its AVT Helios line, an automatic 100 percent inspection system designed for labels and other narrow web printing applications, which automatically inspects the printed web for defects and imperfections, delivering exceptional quality results and eliminating customer rejections.

Fedrigoni Self-Adhesives is exhibiting for the first time at Labelexpo Americas and brings together all of the Fedrigoni brands under one banner. Visitors can experience new products and services, which are a direct result of the acquisitions over the past two years and the synergies of Acucote, Arconvert, Manter, Ritrama, IP Venus and Tageos.

Fedrigoni Self-Adhesives is exhibiting for the first time at Labelexpo Americas and brings together all of the Fedrigoni brands under one banner. Visitors can experience new products and services, which are a direct result of the acquisitions over the past two years and the synergies of Acucote, Arconvert, Manter, Ritrama, IP Venus and Tageos.  Fix-a-Form International presents a Fold & Fix booklet label machine with a 16.5in web width and the capability to handle 0.75 to 15in leaflet lengths at up to 100 ft/min in multiple modes of operation.

Fix-a-Form International presents a Fold & Fix booklet label machine with a 16.5in web width and the capability to handle 0.75 to 15in leaflet lengths at up to 100 ft/min in multiple modes of operation.FLEXcon optiflex ecofocus products have been developed to maximize the recyclability of PET and HDPE containers, enabling print service providers and brands to achieve sustainability and performance to meet the demands of consumer packaging. Applications include food and beverage, personal care and cosmetics, and household chemical. V-52RE wash-off adhesive on BOPP films separates from PET flake in the reclaim process, increasing the amount of rPET available for future use, while PE films with V-127RE adhesive ensure

performance and recyclability of HDPE containers.

FLEXcon pharmcal are compliant products for a diverse range of pharmaceutical containers and performance requirements, including ampules, vials and syringes, security, blood bag, conceal, and over the counter. Consistent quality and performance are assured with FLEXcon’s four-stage change management process.

FLEXcon nexgen for durable labeling will also be on display. FLEXcon specializes in UL-, cUL-, and CSA-recognized materials intended to bond permanently to surfaces and withstand exposure to harsh environments for the lifetime of durable equipment such as power tools, outdoor power equipment, and heavy machinery.

GEW brings its latest UV LED products to Labelexpo Americas. LeoLED, released in 2019, is GEW’s water-cooled UV LED offering and is fully compatible with GEW’s ArcLED hybrid system. It has a 50mm-wide window to give a long dwell time and is waterproof-sealed for easy cleaning and resilience to dust and ink. The LED array delivers electrical power of 88W/cm and an intensity of 30W/cm2, with minimal light loss due to the direct UV path.

GEW brings its latest UV LED products to Labelexpo Americas. LeoLED, released in 2019, is GEW’s water-cooled UV LED offering and is fully compatible with GEW’s ArcLED hybrid system. It has a 50mm-wide window to give a long dwell time and is waterproof-sealed for easy cleaning and resilience to dust and ink. The LED array delivers electrical power of 88W/cm and an intensity of 30W/cm2, with minimal light loss due to the direct UV path. SmartDFE provides a full software and hardware stack, built around the award-winning Harlequin Direct RIP technology that has been designed to drive the fastest, widest and highest inkjet presses. It is capable of processing fully variable data at high speeds and communicating out to the wider smart print factory, providing valuable information for QA and inspection, press maintenance, and stock control.

It enables inkjet engineering teams to get to market quickly with a future-proofed, high-performance product, whilst allowing them the space and capability to add their own value.

SmartMedia is a new suite of components that simplifies the process of obtaining the best quality and color output from a digital press. Powered by the award-winning PrintFlat and enhanced with powerful color tools from ColorLogic, recently acquired by Hybrid Software Group, SmartMedia packages all the OEM’s reference press settings for each media and ink set into a library of media definitions and, via a wizard-like experience, enables press operators to easily select the appropriate media and ink set combination without needing specialist knowledge.

The company is inviting attendees to explore its GMG ColorServer bundle, complementary software designed to drive ink and time savings through smarter color management automation.

At its booth, GMG Color encourages visitors to get hands-on with printed color-accurate prototype samples, produced with its latest range of equipment. The samples demonstrate that with the right color management and proofing software in place, pin-sharp precision across varying substrates and inks can be made simple.

Grafisk Maskinfabrik exhibits six machines, including the new DC350Flex high speed label finisher fitted with a multi-web module producing multilayer labels using the entire web width. Also, the DC330Mini compact label finisher can be seen converting pre-printed labels. It has several options such as real-time monitoring, full remote control, and job data in the cloud.

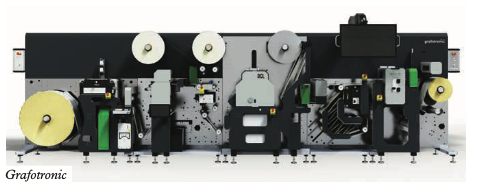

Grafisk Maskinfabrik exhibits six machines, including the new DC350Flex high speed label finisher fitted with a multi-web module producing multilayer labels using the entire web width. Also, the DC330Mini compact label finisher can be seen converting pre-printed labels. It has several options such as real-time monitoring, full remote control, and job data in the cloud. Grafotronic presents three world premieres for the label industry. The workflow automation suite enables the Grafotronic DCL2 to do job change autonomously, handling all job settings automatically. IQ works with a set of cameras monitoring the web and automatically adjusting parameters, taking over all the manual adjustments with a tolerance below +/- 0.1 mm.

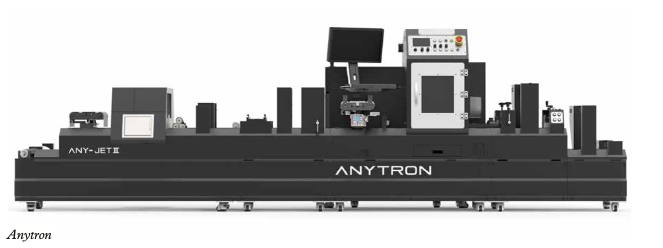

Grafotronic presents three world premieres for the label industry. The workflow automation suite enables the Grafotronic DCL2 to do job change autonomously, handling all job settings automatically. IQ works with a set of cameras monitoring the web and automatically adjusting parameters, taking over all the manual adjustments with a tolerance below +/- 0.1 mm.During the changeover the new machine responds in time with no downtime. The Smart Save function helps to reduce waste to achieve more value with 90 percent Pantone color matching with CMYK only and super smooth single white with 75 percent opacity.

The company is promoting the next-generation LabStar330S Hybrid with added flexo and converting modules. The new design means ‘uplifts the UV inkjet to a whole new level’.

Heraeus Noblelight America showcases infrared and UV LED curing systems suitable for a wide range of label applications, including drying water-based inks, curing UV inks and pressure-sensitive adhesives.

Heraeus Noblelight America showcases infrared and UV LED curing systems suitable for a wide range of label applications, including drying water-based inks, curing UV inks and pressure-sensitive adhesives.

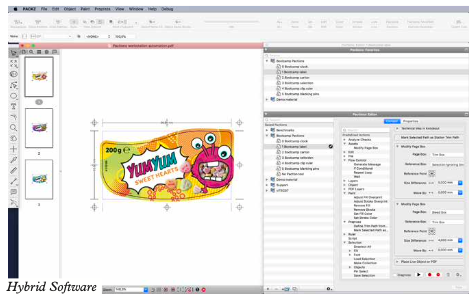

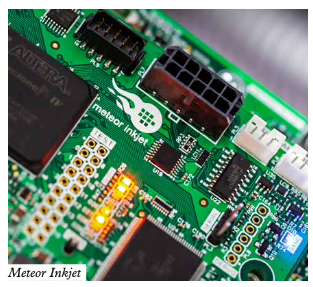

Hybrid Software showcases its recent acquisition of iC3D by showing 3D visualization throughout the entire prepress process. At booth 3015, Hybrid Software and iC3D will join its Hybrid Software Group sister companies, including Global Graphics Software ColorLogic, Xitron and Meteor Inkjet.

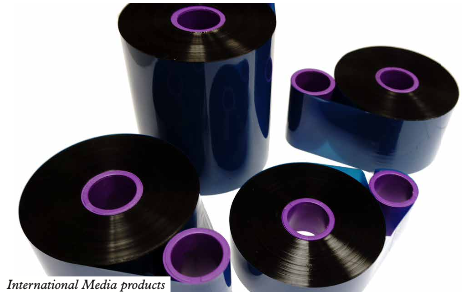

Hybrid Software showcases its recent acquisition of iC3D by showing 3D visualization throughout the entire prepress process. At booth 3015, Hybrid Software and iC3D will join its Hybrid Software Group sister companies, including Global Graphics Software ColorLogic, Xitron and Meteor Inkjet. International Media Products showcases its most recent thermal transfer ribbon addition, the Z200+ wax/resin, offering image durability, abrasion resistance, and high-speed printing capability. As a US-based manufacturer, IMP offers a full line of ‘plug and play’ thermal ribbon technologies for the barcode label and tag printing market. Additionally highlights its flexible package printing ribbons, used for thermal transfer overprinting, including the new 4.0-micron extended length product line. All IMP formulations are halogen-free and ROHS compliant.

International Media Products showcases its most recent thermal transfer ribbon addition, the Z200+ wax/resin, offering image durability, abrasion resistance, and high-speed printing capability. As a US-based manufacturer, IMP offers a full line of ‘plug and play’ thermal ribbon technologies for the barcode label and tag printing market. Additionally highlights its flexible package printing ribbons, used for thermal transfer overprinting, including the new 4.0-micron extended length product line. All IMP formulations are halogen-free and ROHS compliant.INX International Ink is featuring many of its products and new equipment, including INXFlex Contour a UV and LED dual cure flexographic ink system that produces shrink sleeve labels.

INXFlex Contour piggybacks off Genesis washable label inks. A recycle-friendly ink system, it recently added a new flexo version and UV curable primer that makes INXFlex Contour washable too.

INX partnered with VerifyMe announced the development of VerifyInk, a covert ink technology to help provide brand protection of products in the marketplace. The newest addition to the security inks product line runs on direct-to-product continuous inkjet (CIJ) printers. When used in tandem with VerifyMe’s proprietary and patented reading devices, it can identify counterfeit products across all markets including consumer goods, pharmaceuticals, and food and beverage, says the company.

INXShield UV Flexo and GS Slip coatings represent the first in a new line of functional coatings for packaging applications. Formulated with BioCote antimicrobial technology to protect the coating by inhibiting odor and staining microbes on the surface, INXShield is validated and quality control tested regularly by an independent testing facility using the ISO 22196:2011 test method.

The Triangle brand of XJL UV Curable Inkjet inks follow in the tradition of exceptional alternative ink products.

The NW350 is the newest addition to the narrow web series of UV Digital Label printers, designed to combine printing and conversion to produce brilliant color printed labels at a maximum printing width of 350mm or 13.78 in, the NW350 delivers single pass output up to 160 ft/min on any label stock. This product includes quality inks, making it ideal for printers looking to meet the demand for productive, short-run digital printing.

Click here for more information.

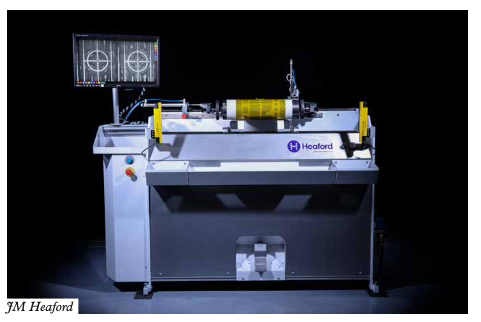

JM Heaford demonstrates its range of plate mounters. Visitors can see Heaford’s AutoMounter, the system which eliminates operator judgment from the mounting process and reduces press downtime. The Label AutoMounter is configurable for multiple presses and offers options including pre-register compatibility, plate and tape cutters and a sleeve exchange unit. The company also shows a semi-automatic FTS model plate mounter.

JM Heaford demonstrates its range of plate mounters. Visitors can see Heaford’s AutoMounter, the system which eliminates operator judgment from the mounting process and reduces press downtime. The Label AutoMounter is configurable for multiple presses and offers options including pre-register compatibility, plate and tape cutters and a sleeve exchange unit. The company also shows a semi-automatic FTS model plate mounter. Karlville displays the Plus series machine combo, K3 Plus Seamer and iPlus Inspector. The K3 Plus is its third-generation seaming machine with folding system that addresses shrink sleeve seaming issues. It comes with a fully automated setup and feedback loop. The machine runs a +/-0.15mm lay flat tolerance with a friction-free forming system. Operators can position seam up to 5mm from fold. Laser perforation (cross and continuous perforations) integration with turret unwind and rewinds are optional.

Karlville displays the Plus series machine combo, K3 Plus Seamer and iPlus Inspector. The K3 Plus is its third-generation seaming machine with folding system that addresses shrink sleeve seaming issues. It comes with a fully automated setup and feedback loop. The machine runs a +/-0.15mm lay flat tolerance with a friction-free forming system. Operators can position seam up to 5mm from fold. Laser perforation (cross and continuous perforations) integration with turret unwind and rewinds are optional.

Kroenert promotes coating and laminating lines for web materials such as paper, foil, film, cardboard and non-woven. The product range includes customized production and laboratory lines. Kroenert offers systems with web widths of up to 3,300mm, coating thicknesses of more than 1mm to a minimum of 100 nanometres and processing speeds from 0.5m/min up to 2,000m/min. Besides topics like digitalization in coating technology, the company will also focus on innovative user interfaces and sustainability.

Kroenert promotes coating and laminating lines for web materials such as paper, foil, film, cardboard and non-woven. The product range includes customized production and laboratory lines. Kroenert offers systems with web widths of up to 3,300mm, coating thicknesses of more than 1mm to a minimum of 100 nanometres and processing speeds from 0.5m/min up to 2,000m/min. Besides topics like digitalization in coating technology, the company will also focus on innovative user interfaces and sustainability. KTI promotes the MTR Series of turret rewinder in web widths up to 22in (558mm), roll diameters up to 16in (406mm), and speeds up to 750 ft/min (228m/min). The MTR Series turret rewinder has four spindles, an integrated dancer for superior web control and PLC touch screen controls. In addition, a new roll closure system is available with in-line print and apply technology, allowing customers to add various product and production information to the roll closure labels, including product codes, lot numbers, job numbers and date of production. Additional options can be added, including automatic core loading and a slitting module.

KTI promotes the MTR Series of turret rewinder in web widths up to 22in (558mm), roll diameters up to 16in (406mm), and speeds up to 750 ft/min (228m/min). The MTR Series turret rewinder has four spindles, an integrated dancer for superior web control and PLC touch screen controls. In addition, a new roll closure system is available with in-line print and apply technology, allowing customers to add various product and production information to the roll closure labels, including product codes, lot numbers, job numbers and date of production. Additional options can be added, including automatic core loading and a slitting module. Kurz showcases its DM-Uniliner and the MJETeco. The MJETeco from MPrint, a Kurz company, is a standalone UV inkjet product for late-stage customization. The MJETeco handles a wide variety of applications, whether users are printing barcodes or serial numbers for security labels, or complete back labels for wine and spirits. The company also demonstrates its Digital Metal technology.

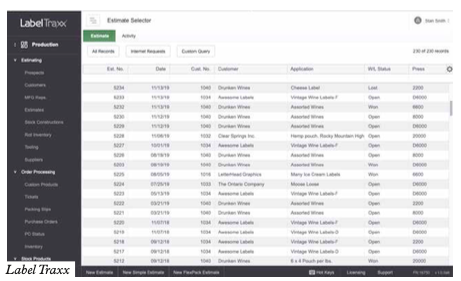

Kurz showcases its DM-Uniliner and the MJETeco. The MJETeco from MPrint, a Kurz company, is a standalone UV inkjet product for late-stage customization. The MJETeco handles a wide variety of applications, whether users are printing barcodes or serial numbers for security labels, or complete back labels for wine and spirits. The company also demonstrates its Digital Metal technology.  Label Traxx unveils its Version 9.0 workflow software. In response to ongoing industry consolidation, the Enterprise Edition will be previewed, offering a set of capabilities designed to serve the requirements of multi-site organizations. The company previews new CRM features with the Customer Service suite, including Rapid Quoting. The recently-added Inventory Forecast Tool provides the operations team insights and alternatives to respond to supply chain challenges in real-time from its Automated Planning & Scheduling Suite. The expanded team will also answer questions about new subscription plans and cloud hosting alternatives.

Label Traxx unveils its Version 9.0 workflow software. In response to ongoing industry consolidation, the Enterprise Edition will be previewed, offering a set of capabilities designed to serve the requirements of multi-site organizations. The company previews new CRM features with the Customer Service suite, including Rapid Quoting. The recently-added Inventory Forecast Tool provides the operations team insights and alternatives to respond to supply chain challenges in real-time from its Automated Planning & Scheduling Suite. The expanded team will also answer questions about new subscription plans and cloud hosting alternatives.

Lundberg demonstrates Lundberg Tech MatrixCompactor 140 label matrix waste removal system. It provides in-line waste handling of matrix and trim waste with adhesives from label presses. The MatrixCompactor 140 captures the matrix and trims directly from the press, and the cutter chops the waste into small-sized pieces for easy transport in the non-stick pipe system. The matrix waste is subsequently compacted in the integrated WasteCompactor. Lundberg waste handling experts are available to discuss central waste handling technology for label and flexible packaging providers.

Lundberg demonstrates Lundberg Tech MatrixCompactor 140 label matrix waste removal system. It provides in-line waste handling of matrix and trim waste with adhesives from label presses. The MatrixCompactor 140 captures the matrix and trims directly from the press, and the cutter chops the waste into small-sized pieces for easy transport in the non-stick pipe system. The matrix waste is subsequently compacted in the integrated WasteCompactor. Lundberg waste handling experts are available to discuss central waste handling technology for label and flexible packaging providers.

Meca, a Precision Roll Solutions company, displays lightweight, ergonomic print sleeves in booth 3000. Jamie Morales, Meca printing expert, is available on-site to help attendees compare a lightweight sleeve to the sleeves they have in their facility and describe how Meca’s proprietary design improves print quality and overall efficiency - from resin-saturated nonwovens that resist thermal expansion to a smooth-as-glass inside surface that holds the sleeve securely in place. Meca print sleeves are manufactured in Green Bay, Wisconsin, helping printers to avoid the unpredictability and rising costs that are inherent with overseas suppliers.

Meteor Inkjet showcases its portfolio of industrial products for labels and packaging, including a range of drive electronics for all major industrial inkjet printheads; ready-to-use digital front ends and workflow solutions; software development kits allowing custom printers to be built from the ground up; and a complete suite of tools and services to support machine builders in the design and optimization of print systems.

Meteor Inkjet showcases its portfolio of industrial products for labels and packaging, including a range of drive electronics for all major industrial inkjet printheads; ready-to-use digital front ends and workflow solutions; software development kits allowing custom printers to be built from the ground up; and a complete suite of tools and services to support machine builders in the design and optimization of print systems.In particular, Nazdar is highlighting its latest LED curing Nestlé compliant inks, coatings, and adhesives. Additionally, the company will promote its new water-based flexible packaging inks.

Phoseon Technology introduces Nexus One sustainable UV LED curing products for flexographic printing applications. All Nexus One UV LED curing products from offer a 5-year warranty and enable quality applications at fast press speeds.

Phoseon Technology introduces Nexus One sustainable UV LED curing products for flexographic printing applications. All Nexus One UV LED curing products from offer a 5-year warranty and enable quality applications at fast press speeds. Prati promotes its DigiFastone digital finishing line based on the company’s Futura field-upgradable open platform technology.

Prati promotes its DigiFastone digital finishing line based on the company’s Futura field-upgradable open platform technology.Features of the modular hybrid technology include multiple die-cutting stations, rotary flexo and flatbed screen printing units, up to seven colors, including opaque white, with 600 DPI native print resolution, combining the productivity of flexo printing with the flexibility offered by rapid job change digital technology. The N610i integration module incorporates Domino’s automated, i-Tech productivity features for enhanced flexibility and reliability.

Rotometal showcases MCA Magnetic Cylinders with an aluminum body. The company has created a magnetic cylinder that maintains high strength and hardness while significantly reducing weight by utilizing aerospace-grade aluminum. This is said to make them lighter, easier to handle and helps reduce transport costs and energy consumption while maintaining the quality and consistency of traditional magnetic print cylinders.

Rotometal showcases MCA Magnetic Cylinders with an aluminum body. The company has created a magnetic cylinder that maintains high strength and hardness while significantly reducing weight by utilizing aerospace-grade aluminum. This is said to make them lighter, easier to handle and helps reduce transport costs and energy consumption while maintaining the quality and consistency of traditional magnetic print cylinders.S-One Labels & Packaging shares its latest innovations, including laminating technologies, coatings and varnishes, finishing equipment, slitters, and rewinders, Cast and Cure products for Ebeam holograms, ink control and dispensing equipment, overlaminate films, prelaminated metallized films, as well as clear and white.

The company is also showcasing its recyclable ReTreve EVOH high barrier flexpack films and Lomi-approved ReEarth compostable films.

Booth visitors have a chance to win a Lomi countertop composter.

Tom Hauenstein, vice president of sales at S-OneLP will be also a moderator and presenter at panel discussion: Opportunities beyond print and stick labels on Wednesday, September 14 at 1pm.

Screen showcases the Truepress Jet L350UV SAI, the latest model from the L350UV series with a resolution of 600x600 DPI and speeds up to 60m/min. The Truepress Jet L350UV SAI series prints in CMYK plus white, blue and orange options. Automated head cleaning is activated by the press of a button.

Screen showcases the Truepress Jet L350UV SAI, the latest model from the L350UV series with a resolution of 600x600 DPI and speeds up to 60m/min. The Truepress Jet L350UV SAI series prints in CMYK plus white, blue and orange options. Automated head cleaning is activated by the press of a button. A standalone subsidiary of Mactac, owned by Lintec, Spinnaker is becoming a one-of-a-kind, world-class specialty labeling company. Its business model is centered on unique and customized opportunities in specialty labeling — from custom product offerings to a high-touch custom service model.

Spinnaker offers a comprehensive line of pressure-sensitive roll products designed to help customers’ products stand out and are used in many industries and markets, including pharmaceutical, industrial, cold, frozen food and beverage and more.

Labelexpo attendees will be able to learn more about the company’s specialty roll products and Lintec specialty products available from Spinnaker, including cryogenic labels designed for harsh environments and temperatures as low as -320°F, clear and red gloss Void labels and oil tolerant labels.

Using its ‘5Rs’ framework (Reuse, Reduce, Renew, Recycle and Redesign) as a guide, Sun Chemical invests significantly in R&D to improve the eco-efficiency and sustainability of the packaging that utilizes its inks, coatings and adhesives to support a circular economy.

Labelexpo Americas visitors are able to learn about the bio-renewable, compostable and recyclable products under Sun Chemical’s SunEco portfolio, including SolarFlex CRCL for shrink and non-shrink applications, SolarFlex High Adhesion Technology, SunCure mono-web coatings, SunVisto AquaGreen renewable ink series, MX12 ink dispensing technology and SolarWave UV-LED inks.

Complementing its product line-up, Sun Chemical also presents its range of SunInspire specialty inks and coatings for label applications, which add an extra dimension and look and feel to label applications. Sun Chemical’s booth visitors will also see SunColorBox offering a unique set of tools and services – from site assessments and full-color audits to matching and validating colors to hosting digital libraries of spot colors. Moreover, the company will demonstrate SunMotion, an alternative to backlit signage and LCD displays.

Attendees of the trade show can hear from Mohammad S. Farahat, Ph.D., director of R&D and Novel Device Technology at Sun Chemical, who will present a session on Wednesday, September 14, at 9:50 am on special effect inks and coatings during the Label Academy Masterclass: Digital Embellishment, a five-hour global training class held during the show.

Tharstern promotes Tharstern Cloud for labels, a new MIS technology built entirely from the ground up to help label converters digitize their business processes and automate their production workflow. It uses an ‘API First’ approach, featuring a fully accessible public API allowing any data within the MIS to be written and read by any external application at any level.

Tharstern promotes Tharstern Cloud for labels, a new MIS technology built entirely from the ground up to help label converters digitize their business processes and automate their production workflow. It uses an ‘API First’ approach, featuring a fully accessible public API allowing any data within the MIS to be written and read by any external application at any level.  Tootech is launching Laser Label Printer, which images directly onto the middle layer of the label after passing through the label’s surface. The surface layer protects the barcode and character image so they cannot be erased by friction or chemicals. Tootech already supplies this printer to companies such as Samsung Electronics

Tootech is launching Laser Label Printer, which images directly onto the middle layer of the label after passing through the label’s surface. The surface layer protects the barcode and character image so they cannot be erased by friction or chemicals. Tootech already supplies this printer to companies such as Samsung Electronics These label films offer ink adhesion and printability and moisture resistance. The clear film has superior clarity, and the white film’s opacity, brightness, and gloss are also of superior quality and may allow the converter to eliminate white ink. The TLF portfolio is compatible with flexo and gravure presses, energy-curable inks, and water-based, solvent, and solventless laminators. In addition, the new polypropylene film line allows the company to provide customers with larger rolls that offer more lineal footage. That means converters will have fewer roll changes and splices.

Toray team is also sharing information about new PSL label films that are in development. The diverse portfolio will include uncoated and coated BOPP facestocks for clear, metallized, and cavitated and solid core white label applications.

Tower Products releases its new SmartFlex UV Wash FX, a low odor product for cleaning UV flexographic inks from plates and machinery. When used as directed, the product will not swell photopolymer printing plates and can be applied by hand or used in an automatic plate cleaning unit. The product can be mixed with water or used full strength for all UV ink cleaning applications and is also an outstanding cleaner for UV Screen Printing inks.

Tower Products releases its new SmartFlex UV Wash FX, a low odor product for cleaning UV flexographic inks from plates and machinery. When used as directed, the product will not swell photopolymer printing plates and can be applied by hand or used in an automatic plate cleaning unit. The product can be mixed with water or used full strength for all UV ink cleaning applications and is also an outstanding cleaner for UV Screen Printing inks.Newly released during Labelexpo America 2022, is the Univacco 724 Series hot-stamping foil, specifically developed for hot stamping on a wide variety of wine label stocks providing excellent transfer at high-speed stamping on rotary and vertical presses with wide range of coverage from fine to broad.

UVitec Printing Ink presents its UV/LED curable flexographic and rotary screen inks, coatings and adhesives uniquely formulated for shrink label applications, which are addressing common industry shortcomings. The range includes overprintable or controlled COF high opacity white inks, gloss clears, scuff resistant mattes, high build gloss and matte tactiles, soft touch and sandy textures, cold foil adhesives, glitters, pearlescence, and additional specialties. All products are Benzophenone and PFOA free, with formulations available for Reach, Nestle and CA Prop 65 Compliance. The company also presents a full line of UV/LED PSA’s and release coatings for ECL’s, IRC’s and other constructions.

XSYS manufactures all its plates, imagers and processors as well as sleeves and adapters in house, giving the company full control of the whole production process and the ability to deliver more coherent service and support. The company has one of the widest portfolios of products and brands, which includes nyloflex solvent and nyloflex Xpress thermal plates and equipment, nyloprint letterpress plates and equipment, nylosolv washout solvent, rotec sleeves and adapters, ThermoFlexX TfxX Imagers, ThermoFlexX Catena Plate Processing equipment, and Woodpecker surface screening products.

Zeller+Gmelin unveils its newest development in UV/LED prime label opaque white inks. The new ink formula was developed to provide advanced opacity, brighter hues, and smoother lay downs for dual-cure opaque white flood coat applications. With the new ink chemistry, converters can achieve the ultimate in opaque white laydowns in a single pass, saving money, time and the environment.

Zeller+Gmelin unveils its newest development in UV/LED prime label opaque white inks. The new ink formula was developed to provide advanced opacity, brighter hues, and smoother lay downs for dual-cure opaque white flood coat applications. With the new ink chemistry, converters can achieve the ultimate in opaque white laydowns in a single pass, saving money, time and the environment.Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.