Introducing label dispensing and application technology

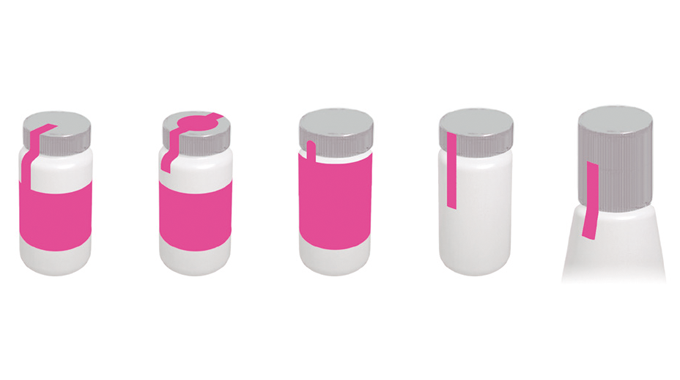

The rapid growth in the use of pressure-sensitive labels for product decoration, marking and identification has been one of the success stories of the last fifty years. Also known today as self-adhesive labels, they offer labeling flexibility, simplicity of application without the use of wet adhesives, quick label applicator line changeovers and the potential to add coding, marking and overprinting close to the point of application on almost any size or shape of product.

Continuous innovation and marketing by substrate suppliers, technology manufacturers and converters has done much to make pressure-sensitive labels so widely used. Equally important was the development of technologies for die-cutting labels to shape, removing the matrix waste and then being able to accurately dispense and apply individual pressure-sensitive labels to a wide variety of product shapes and sizes.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.